Harnessing the raw power of a Harley is an unbeatable thrill; yet, like every mechanical marvel, it’s not exempt from minor hitches now and then.

One such issue is the paralyzing hydraulic clutch problem, an ordeal every Harley fan dreads. But take heart—this is not the end of the road. With knowledge and a bit of elbow grease, you can navigate this bumpy ride smoothly and keep your Harley roaring.

Shifting gears, literally and figuratively, becomes less daunting when armed with the right information.

So let’s dive deep under the hood (tank?), dissect the problem, and most importantly, discover what to do when your Harley’s hydraulic clutch problems gives you trouble. Ready to rev up your problem-solving skills? Let’s ride!

What Kind of Clutch Do Harleys Have?

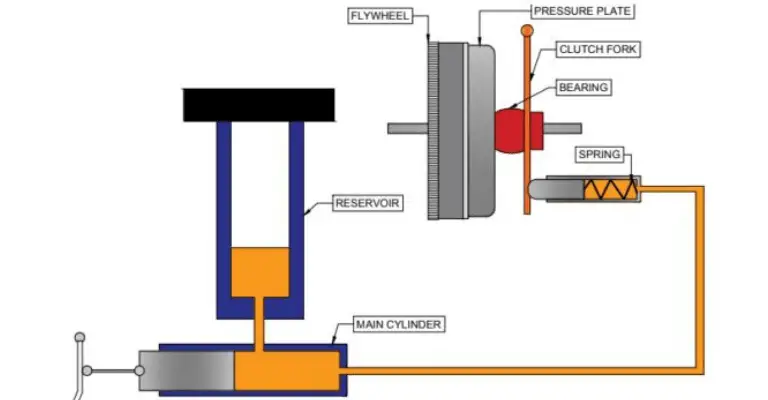

Harley Davidson motorcycles typically use hydraulic clutches. This system operates on hydraulic fluid pressure to engage and disengage the clutch, facilitating smooth gear changes. Unlike manual clutches, which require the rider to operate a lever to change gears, hydraulic clutches require less physical effort, resulting in a more comfortable ride.

In the following infographic, consider that there is a clutch lever at the start of the system (left side):

[su_youtube_advanced url=”https://www.youtube.com/watch?v=gd3708CBZtE”]

Hydraulic vs Cable Clutches

Hydraulic clutches, like those found in Harleys, and cable clutches each have their unique characteristics.

Hydraulic Clutches: These clutch systems use hydraulic fluid to transmit pressure from the master cylinder (operated by the clutch lever) to the slave cylinder (which engages/disengages the clutch). They offer smoother operation, require less maintenance, and provide a more consistent feel than cable clutches.

Cable Clutches: These operate using a physical cable that runs from the clutch lever to the clutch itself. When the rider pulls the lever, it pulls the cable, disengaging the clutch. Although they might require more frequent adjustment and maintenance than hydraulic clutches, cable clutches are simpler in design and easier to repair in case of failure.

Read next: Harley EITMS Problems

Here’s a visual representation of these differences, along with some others:

| Aspect | Hydraulic Clutch | Cable Clutch |

|---|---|---|

| Functionality | Uses hydraulic fluid to transmit clutch engagement and disengagement. | Uses a cable to transmit clutch action, typically made of steel. |

| Clutch Lever Feel | Provides a smoother and lighter lever pull due to hydraulic assistance. | Often has a more direct and tactile feel, but can be heavier depending on cable routing and adjustment. |

| Maintenance | Generally requires less maintenance. Hydraulic fluid changes are periodic. | May require occasional lubrication and adjustment to maintain proper functioning. Cable replacement might be needed over time due to natural wear. |

| Adjustability | Limited adjustability. Hydraulic clutches may have less customization in terms of lever engagement points | Offers more adjustability, allowing for precise fine-tuning of clutch engagement points. |

| Performance Consistency | Provides more consistent performance over time to due hydraulic assistance. | Performance might vary depending on cable condition and adjustment status. |

The Dreaded Harley Davidson Clutch Problems

Despite the advantages of hydraulic clutches, they can also present some challenges. Let’s explore some of the most common Harley hydraulic clutch problems:

Seal Deterioration (Loss of Fluid)

One common issue with hydraulic clutches is the deterioration of the seals, which can lead to fluid leakage. If the fluid level drops significantly, the clutch may fail to disengage properly, leading to your Harley’s hydraulic clutch not disengaging.

Clutch Sticking (Worn Clutch Plates)

Clutch plates can wear out over time, leading to a clutch sticking issue. When this happens, the clutch plates fail to disengage completely when the clutch lever is pulled. As a result, the bike may continue to move even when the rider intends to stop, potentially leading to dangerous situations.

Related: Harley Goes Into Gear But Won’t Move? Help Is Here!

Clutch Slipping (Not Properly Engaging)

Clutch slipping is another common problem where the clutch fails to engage fully. This issue can manifest as a sudden loss of power when accelerating or difficulty in shifting gears. Causes can range from worn-out clutch plates to incorrect clutch cable adjustment.

Premature Wear (Improper Maintenance)

Inadequate maintenance can lead to premature wear of the clutch system components. For instance, not regularly checking and adjusting the fluid levels can lead to issues like clutch slipping or sticking.

Master Cylinder Failure (It’s a Recall)

The cylinder plays a crucial role in hydraulic clutch systems. It’s responsible for generating the hydraulic pressure that actuates the clutch. However, the master cylinder can fail, leading to total clutch failure. Harley-Davidson has issued recalls in the past due to master cylinder issues.

More About The Recalls

Harley Davidson issued a recall in late 2018 affecting over 238,300 motorcycles worldwide and 3,695 motorcycles in Australia. The recall concerned a potential internal fluid leak in the hydraulic clutch system, which could result in the inability to disengage the clutch, leading to a potential loss of control.

Read next: How Long Do Harleys Last?

[su_button url=”https://theseasonedwrench.com/best-motorcycle-wax/” style=”soft” background=”#f2000d” color=”#ffffff” size=”11″ wide=”yes” center=”yes” icon=”icon: wrench” rel=”nofollow”]Click Here to Learn About The Best Motorcycle Waxes for That Hog[/su_button]

Harley Davidson Clutch Troubleshooting Guide (Identify Your Problem)

Having Harley clutch adjustment issues? Here’s a brief guide to help you troubleshoot:

Clutch Not Disengaging: If the clutch doesn’t disengage when you pull the lever, it might be due to a low hydraulic fluid level or a leak in the clutch system.

Hard Shifting: Difficulty in shifting gears can be due to a misaligned clutch, worn clutch plates, or a problem with the master cylinder.

Clutch Slipping: If the clutch slips and doesn’t engage properly, it could be due to worn clutch plates or a problem with the hydraulic system, such as a leak or low fluid level.

Clutch Sticking: Sticking can be caused by issues with the clutch basket or worn friction plates.

How To Fix Harley Hydraulic Clutch Problems

Here’s how to address some common Hydraulic clutch related problems in Harleys:

Seal Deterioration (Loss of Fluid): if the clutch seals are deteriorating, replace them immediately. Also, ensure that the hy

draulic fluid is topped up to the recommended level.

Clutch Sticking (Worn Clutch Plates): If the clutch plates are worn, replace them with new ones. Also, check the clutch basket for any damages.

Clutch Slipping (Not Properly Engaging): If the clutch is slipping, inspect the clutch plates for wear and replace if necessary. Also, check the hydraulic fluid level and top up if necessary.

Premature Wear (Improper Maintenance): Regular maintenance is vital to prevent premature wear. This includes checking and adjusting the hydraulic fluid level and replacing worn-out components as necessary.

Master Cylinder Failure (It’s a Recall): If you suspect a failure of this component, get your bike inspected at an authorized Harley Davidson service center. If your bike is under a recall, the repair will be done free of charge.

How To Maintain A Harley’s Hydraulic Clutch System (Prevent The Problems)

Proper maintenance is key to preventing clutch problems in your Harley. Here are some tips:

Regularly Check Fluid Levels: Check the hydraulic fluid levels at regular intervals and top up if necessary.

Inspect Seals and Hoses: Regularly inspect the seals and hoses for leaks or damage. Replace them if necessary.

Regular Servicing: Schedule regular servicing at an authorized Harley Davidson service center. They can inspect the hydraulic system and perform necessary adjustments or replacements.

Avoid Aggressive Riding: Aggressive riding can cause premature wear of the clutch system. Always ride gently and use the clutch smoothly for gear changes.

Harley Davidson Hydraulic Clutch Adjustment Procedure (Step-By-Step)

Despite being self-adjusting, the hydraulic clutch might need occasional adjustments due to wear and tear. Here’s a step-by-step guide:

Tools Needed:

- Wrench set

- Screwdriver (if necessary)

- Brake fluid (specified for your motorcycle)

Step-by-Step Guide:

Preparation:

- Park your motorcycle on a level surface and turn off the engine.

- Make sure you have proper safety gear on, including gloves and eye protection.

- Allow the motorcycle’s engine and exhaust components to cool down if it has been recently ridden.

Locate the Clutch Master Cylinder:

- The clutch master-cylinder is usually located on the left handlebar, near the clutch lever. It’s a reservoir that holds hydraulic fluid.

Check Fluid Level:

- Open the clutch master-cylinder reservoir cap and check the fluid level. It should be between the “MIN” and “MAX” marks. If needed, add the specified brake fluid to bring it to the correct level. Be cautious not to spill any fluid on your motorcycle’s paint or finish.

Inspect Lever and Cable:

- Ensure the clutch lever operates smoothly without any binding or resistance.

- Check for any visible leaks or damage in the hydraulic lines and connections.

Locate the Clutch Slave Cylinder:

- The clutch slave cylinder is typically located on the engine casing, near the clutch cover.

Bleed the Hydraulic System (if necessary):

- If you’ve recently replaced any hydraulic components or if you notice air bubbles in the hydraulic system, you may need to bleed the clutch system. Follow the bleeding procedure outlined in your motorcycle’s service manual.

Adjustment:

Harley Davidson hydraulic clutches are generally self-adjusting. As the clutch wears, the system compensates automatically. However, if you notice that the clutch engagement point is too early or too late, follow these steps to make a slight adjustment:

- Locate the adjustment nut on the clutch lever perch (near the handlebar).

- Loosen the locknut with a wrench.

- Turn the adjustment nut clockwise to move the engagement point closer to the grip or counterclockwise to move it away.

- Tighten the locknut after making the adjustment.

Test the Clutch:

- Start the engine and pull the clutch lever in. The lever should feel smooth and engage the clutch without excessive effort.

- Shift through the gears while keeping the clutch lever pulled in. The motorcycle should shift smoothly and without any resistance.

Final Check:

- Ensure the clutch lever returns to its original position after releasing it. There should be no dragging or slipping of the clutch.

Recheck Fluid Level:

- After adjusting the clutch, make sure the clutch master-cylinder reservoir cap is securely tightened.

Clean Up:

- Clean any spilled brake fluid with a damp cloth to avoid damaging the motorcycle’s finish.

Here’s a video detailing the steps necessary to “adjust” your hydraulic clutch. In reality, it’s simply a hydraulic fluid service.

[su_youtube_advanced url=”https://www.youtube.com/watch?v=q-pNnvXqDxY”]

FAQs and Related Questions

What are the common problems with Harley hydraulic clutches?

Common problems with Harley hydraulic clutches include seal deterioration leading to fluid leakage, worn-out clutch plates causing clutch sticking, clutch slipping due to improper engagement, premature wear due to improper maintenance, and master cylinder failure.

When did Harley stop using hydraulic clutches?

Harley Davidson issued a recall in 2018 due to issues with the hydraulic clutch systems on certain models. However, Harley Davidson motorcycles continue to use hydraulic clutches.

Why did Harley recall their motorcycles?

Harley Davidson issued a recall due to potential internal fluid leak in the hydraulic clutch system, which could result in the inability to disengage the clutch, leading to a potential loss of control.

How do I know if my Harley clutch is slipping?

A slipping clutch may manifest as a sudden loss of power when accelerating, difficulty in shifting gears, or the motorcycle continuing to move even when the clutch lever is pulled.

What else could be wrong with my bike besides needing new clutch parts?

Besides clutch problems, issues like engine problems, transmission issues, brake system problems, and electrical system issues could also affect your motorcycle’s performance.

Conclusion

Understanding the common Hydraulic clutch problems in Harleys, and how to troubleshoot them can enable you to maintain your Harley Davidson motorcycle in excellent condition. Regular maintenance, timely replacement of worn-out parts, and proper clutch use can help prevent these issues. However, if you encounter any persistent problems, it’s best to consult an authorized Harley Davidson service center.