Harley-Davidson motorcycles are known for their distinctive sound and performance, but like any mechanical system, they rely on a symphony of well-engineered components to deliver their iconic ride. One crucial part that plays a significant role in the bike’s primary drive system is the compensator. It acts as a shock absorber, protecting the engine and drivetrain from the harsh impacts of the vehicle’s powerful torque operations. A well-designed Harley compensator is essential for smooth power delivery, reducing wear on the drivetrain and improving the overall lifespan of the motorcycle’s engine components.

Choosing between the Best Harley compensator upgrades is a vital decision for any rider looking to enhance the performance and reliability of their bike. A high-quality compensator not only smooths out engine pulses and dampens the noise and vibration but also provides instant torque response. Given the range of models and preferences, aftermarket options such as the Darkhorse Man-O-War Compensator sprocket and the Screamin’ Eagle Big Twin Compensator have emerged to offer improved durability and performance over the OEM component. Motorcyclists often seek these upgrades after experiencing common issues with the stock compensator, such as excessive noise or a drop in performance.

The aftermarket for Harley compensators is ripe with contenders claiming to offer the best solution to these issues, from the instant torque responsiveness of the Darkhorse Man-O-War Motorsprocket to the reliability and performance of the Screamin’ Eagle and Drag Specialties kits. Riders must weigh the benefits, such as improved noise reduction and longevity, against considerations like cost and compatibility with their specific Harley-Davidson model. Maintaining the compensator is also critical as it ensures the ride remains smooth and reduces the risk of damage to the primary drive system, making the choice of the best Harley compensator a key consideration for the discerning motorcyclist. So where do we start? Oh, my favorite compensator:

Chase’s Compensator Choices

Get The Man O’ War Compensator! (#1)

BDL Compensator Sprocket Kit (for all Big Twin Years: 2006-2024) (#2)

Overview of the Harley Compensator and Its Importance

The Harley compensator plays a pivotal role in enhancing the motorcycle’s performance by reducing stress on the drivetrain. This essential component contributes to both the durability and smooth operation of Harley-Davidson models.

Purpose and Function

The primary purpose of the compensator is to serve as a mechanical buffer between the motor and the drivetrain. It absorbs and distributes shock from the engine’s power pulses, preventing them from causing harsh impacts within the drivetrain components. In essence, the compensator safeguards against the jarring start-up clunks and smoothens the power delivery, contributing significantly to a Harley’s overall performance.

Key Components

Among the key components of the compensator system is the compensator sprocket, which works in tandem with other parts to fulfill its duty. This sprocket – specifically engineered for Harley-Davidson bikes – is designed to handle the high horsepower and torque levels these bikes can produce. The efficient design minimizes vibrations and ensures longevity and effectiveness of the compensator mechanism.

Significance for Harley-Davidson Models

For Harley-Davidson models, the compensator’s significance cannot be overstated. It ensures a smoother ride by reducing the potential for discomfort caused by engine vibrations transmitted to the rider. Additionally, by mitigating premature wear on the drivetrain, it contributes to the reliability and longevity of these motorcycles, which are known for their iconic performance. The proper operation of a Harley compensator is integral to the maintenance of the bike’s overall health and rider satisfaction.

Common Compensator Types and Their Variations

Understanding the different types of compensators available for Harley-Davidson motorcycles is crucial for choosing the right upgrade or replacement. These critical components ensure smooth power transfer within the primary drive system and can significantly affect performance and sound.

Stock Compensators

Stock compensators are the standard equipment installed on Harley-Davidson motorcycles. Designed for the average rider, they balance durability with performance. Twin Cam and M8 engines, for example, come with OEM compensators that are adequate for most situations. Over time and under extreme conditions, however, stock compensators can wear out, leading to noise or operational issues.

Aftermarket Alternatives

Aftermarket compensators offer enhanced performance and durability over stock options. Baker Drivetrain produces a high-quality Baker compensator, known for its robustness and reliability. Another notable upgrade comes from the Screamin’ Eagle Big Twin Compensator by Harley-Davidson, which replaces stock sprocket compensators in Big Twin engines. S&S and Twin Power are alternative brands that manufacture aftermarket compensators, each with its unique engineering contributing to a smoother ride. V-Twin manufacturers also offer compensator upgrades that can help reduce noise and improve longevity. When considering an aftermarket compensator, aspects such as material quality, design improvements, and compatibility with the existing drive system are key factors.

- Baker compensator: Renowned for addressing the weaknesses in stock designs.

- Screamin’ Eagle: Performance-oriented, aimed at Big Twin engine upgrades.

- S&S Easy Start Cams: These sometimes include a compensator feature known for reducing engine start-up clunk.

- Twin Power: Offers products that emphasize a balance of quality and affordability.

Fitment and Compatibility

When selecting the best compensator for a Harley-Davidson, it’s crucial to ensure compatibility with the specific model and to understand how the component can affect the motorcycle’s performance and ride quality.

Model-Specific Fitment

The correct compensator must be chosen based on the exact model of the motorcycle, including Dyna, Softail, Touring models such as the Road King, Street Glide, Electra Glide, and Road Glide. Each series may have distinct specifications:

- Dyna & Softail: Fitment varies widely within these families, including models like the Low Rider S; check exact year and model compatibility.

- Touring Models: Specially tuned compensators are available for these heavier bikes, which may require more robust components.

A detailed compatibility list is typically provided by the manufacturer. For example:

| Motorcycle Series | Model |

|---|---|

| Dyna | All Models (Year Specific) |

| Softail | Low Rider S, Others |

| Touring | Road King, Street Glide |

| Touring | Electra Glide, Road Glide |

Chase’s Second Choice

Twin Power Compensator Sprocket Kit (Softails, Touring, and Dynas Between 1994-2006)

Impact on Performance and Ride Quality

The choice of compensator also impacts the motorcycle’s performance and ride quality, with key considerations including:

- Torsional Vibration Dampening: A high-quality compensator should effectively reduce vibration, improving the ride quality.

- Drive System Stability: Proper fitment ensures stability in the primary drive system, affecting overall performance.

It is important to note that incompatible or poorly matched components can lead to excessive noise, reduced performance, and increased wear on the drive train. Therefore, riders must refer to their Harley-Davidson’s specifications when assessing fitment and compatibility.

Installation and Maintenance Tips

Proper installation and routine care are crucial for maximizing the lifespan and performance of a Harley compensator. Attention to detail during the installation process and meticulous maintenance can prevent many common issues associated with compensator sprockets.

Installation Guide

When installing a compensator sprocket kit, it’s essential to follow the manufacturer’s instructions to ensure accuracy. Begin by securing the motorcycle to prevent any movement. Then, one should remove the primary cover to access the compensator. They will need to remove the old compensator sprocket, often involving the removal of the primary chain. When installing the new compensator, it’s vital to apply the correct torque values to the shaft extension and compensator bolt as per the service manual. A spring pack is usually included, and it should be installed with the correct orientation.

Before reassembly, it’s advisable to inspect and, if necessary, replace the washer located behind the compensator bolt. The use of recommended oil and lubricants during assembly is also important. Use only the oil type specified for the primary chaincase, as improper lubrication can cause premature wear.

Routine Care

A consistent maintenance schedule should include checking the condition and tension of the compensator sprocket. Regular inspection will detect early signs of wear, such as noises or vibrations, indicating that the compensator might require attention or replacement.

One should also verify that the compensator bolt remains properly torqued at the manufacturer’s specified intervals. Regularly replacing the primary oil can help maintain the compensator and other primary drive components. The type of oil and replacement frequency can greatly affect the compensator’s longevity and should align with the service manual’s recommendations.

Technical Specifications and Comparisons

In assessing the best Harley compensator, a discerning rider must consider the technical specifications and direct comparisons between OEM and aftermarket options, focusing on tooth count, construction quality, and performance capabilities.

Compensator Specifications

The compensator is a key component in a Harley-Davidson’s primary drive system, tasked with mitigating engine vibration and managing torque transfer. A standard specification found in these models is the 34-tooth compensator sprocket which is crucial for ensuring smooth operation. When scrutinizing technical specifications, the following are critical:

- Tooth Count: A 34-tooth (34T) design is typical across models, contributing to the precise transfer of power.

- Material Durability: High-grade metals are used for enhanced durability.

- Country of Manufacture: Many riders have a preference for components made in the USA, associating them with quality and reliability.

- Performance: The sprocket’s ability to handle high torque outputs without failing is a sign of a high-performance compensator.

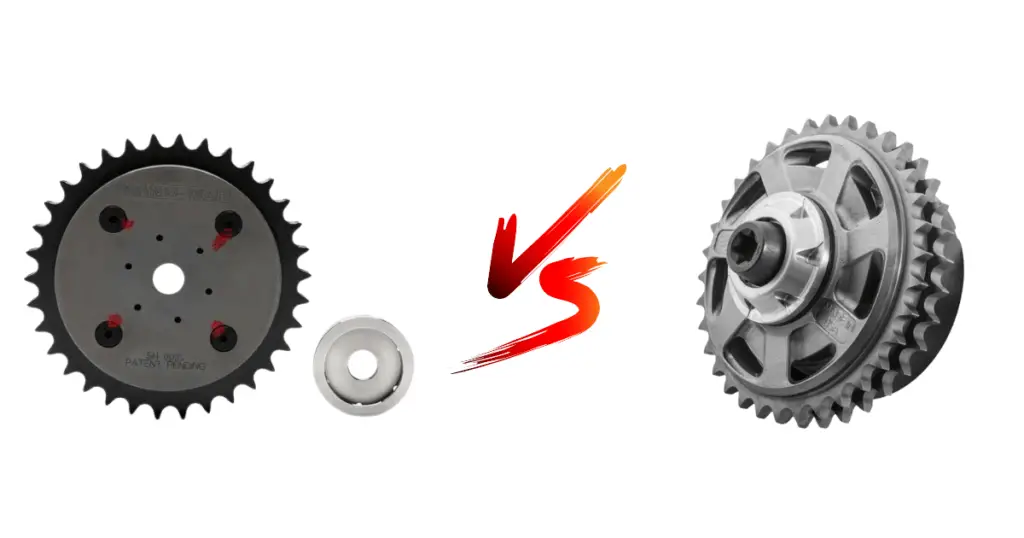

OEM vs Aftermarket Comparisons

When comparing OEM (Original Equipment Manufacturer) to aftermarket compensators, there are several aspects a rider should consider:

- OEM Compensators:

- Specifications: Typically designed for the average rider, ensuring compatibility and reliability.

- Durability: They are engineered to meet factory standards, but over time, may wear out under high-performance demands.

- Aftermarket Compensators:

- Specifications: Often enhanced for high performance, with a focus on reducing slip and improving torque capacity.

- Durability: Upgraded materials and innovative designs in aftermarket options may offer superior durability compared to OEM parts.

A table comparison might look like this:

| Feature | OEM Compensator | Aftermarket Compensator |

|---|---|---|

| Tooth Count | Standard 34T | Standard 34T |

| Durability | Factory standard | Enhanced materials |

| Manufacture | Often made in the USA | Varies by brand |

| Performance | Standard performance | High performance options |

Riders should weigh these specifications against their riding style, performance needs, and budget. Products like the Screamin’ Eagle Big Twin Compensator and Man O’ War compensator are typical examples to compare, with the former being a performance upgrade for the Harley-Davidson Big Twin engines, and the latter acclaimed for its durability and smoother operation.

Issues and Solutions

The Harley compensator plays a crucial role in the motorcycle’s powertrain, ensuring a smooth transfer of power from the engine to the drive train. However, over time, it may develop issues that can lead to noise, vibrations, and durability concerns. This section outlines common problems and their solutions to maintain the compensator’s performance.

Common Compensator Problems

Compensator issues typically manifest through noise and vibrations, which can decrease the durability of motorcycle components. Some standard problems include:

- Sprocket Problems: These may cause a clunking sound and lead to rough startups.

- Starting Issues: Difficulty starting the bike can sometimes be traced back to a worn-out compensator.

- Gear Downshifting Difficulty: Trouble shifting gears might also signal compensator wear.

The solutions often call for:

- Inspecting the Compensator: Regular checks can catch issues early on.

- Replacement Parts: Using high-quality replacement parts ensures greater durability.

- Upgrades: Upgrading to a higher-grade compensator can effectively address these problems.

Troubleshooting Noise and Vibration

Noise and vibration can be more than just annoyances — they can indicate underlying problems with the compensator. To troubleshoot these issues:

- Listen for Clanking Noises: A sound resembling rocks being shaken in a can could signify internal component wear or failure.

- Assess Vibration Levels: Unusual or excessive vibrations may result from compensator issues.

For these symptoms, the solutions involve:

- Tightening Loose Components: This can reduce noise and vibrations.

- Balancing the System: Ensuring proper balance in the compensator system can minimize vibrations.

- Compensator Upgrade: A more modern compensator model may reduce noise and vibrations and improve overall durability.

Rider Feedback and Experiences

Riders have varied experiences with Harley compensators, frequently discussing comfort during travel and the long-term durability of their sprockets. Actual usage often provides the most reliable information for potential buyers.

Comfort and Performance Reviews

Many riders report that a high-quality compensator significantly reduces vibrations, leading to enhanced rider comfort, especially on longer journeys. Professional riders often favor premium brands like Screamin Eagle for smoother power delivery, which is critical during extended rides. User testimonials suggest that an improved compensator:

- Enhances throttle response

- Reduces start-up clunk

- Minimizes engine vibrations

Long-Term Durability Assessments

Durability is paramount in the feedback from long-term users. Riders emphasize the difference between various brands with respect to wear over time. For instance, Baker compensators are often praised for their robust construction and longevity. Owners note:

| Brand | Durability Feedback |

|---|---|

| Screamin Eagle | Less wear compared to stock parts |

| Baker | Superior durability; worth the investment |

| Drag Specialties | Good value for the cost |

| V-Twin Manufacturing | Adequate for budget-conscious riders |

Enthusiasts on forums like V-Twin Forum and Harley Davidson Forums often stress the cost-to-durability ratio as a crucial factor in their assessment, citing that while some solutions are more affordable, they may not offer the same lifespan as pricier alternatives.

Price and Budget Considerations

When selecting a Harley compensator, an individual must evaluate both the cost of the part and its value for money, considering how it will affect overall bike performance.

Cost Analysis

The cost of a Harley compensator typically ranges from $250 to $500 for the component alone. Labor costs can add approximately an hour of work, with hourly rates varying by service location. Therefore, a bike owner can anticipate a complete replacement cost to fall between $350 and $900 for both parts and labor.

- Part cost: $250 – $500

- Labor cost (1 hour): $100 – $400

- Total estimated replacement cost: $350 – $900

Value for Money

In the context of overall performance, investing in a quality Harley compensator can provide substantial benefits. A high-performance compensator not only mitigates vibrations but also ensures the longevity of the primary drive system.

- Performance improvement: Smoother ride, reduced drive system wear

- Long-term savings: Less frequent replacements and repairs

Investing in a reputable brand may yield a higher upfront cost, but it is often justified by the durability and performance enhancement provided, which can translate into cost savings over time for the biker.

Conclusion

When selecting the best compensator for a Harley-Davidson, enthusiasts prioritize durability, performance enhancement, and the reduction of vibrations. To cater to these needs, the Screamin Eagle Compensator stands out due to its design aimed at smoothing power delivery in Harley touring models. It is engineered specifically to minimize vibrations, contributing to a more comfortable and stable ride.

Alternatives like the Baker compensator are also worth mentioning; they often include robust components such as a spring-built rotor, enhancing the longevity and reliability of the motorcycle’s drivetrain. These aftermarket compensators are frequently chosen for their resilience, particularly in high-performance applications.

In contrast, Harley-Davidson’s stock compensator might sufficiently serve casual riders whose demands on their machinery aren’t as intense. The stock option, while not always as robust as its aftermarket counterparts, provides an OEM-level fit and finish, ensuring compatibility with various models.

Cost-effectiveness is another crucial factor, with brands like Drag Specialties and V-Twin Manufacturing offering more affordable solutions without compromising quality. They deliver a balance between performance gains and monetary investment.

The choice of a compensator should align with the rider’s usage patterns, performance expectations, and budget. Harley owners must weigh these factors carefully to ensure their selection maximizes the efficiency and enjoyment of their riding experience.