The Baker compensator is a crucial component of Harley-Davidson motorcycles. It is responsible for quieting down the engine’s primary drive, reducing vibration, and preventing the transmission from getting damaged. However, many riders have reported issues with the Baker compensator, ranging from wear and tear to complete failure.

Some of the most common problems with the Baker compensator include wear issues, lack of lubrication, and stripping teeth. These issues can cause significant damage to the motorcycle, leading to expensive repairs and downtime. While Baker Drivetrain has released a compensator kit for 2007-later Big Twins, many riders are still experiencing problems with their compensators.

If you’re experiencing any Baker compensator problems, it’s important to address them as soon as possible. Ignoring the problem can lead to further damage and costly repairs. In the next sections, we’ll take a closer look at some of the most common problems with the Baker compensator and explore possible solutions.

Related: Guide to Finding The Best Harley Compensator Upgrades Today

Overview of Baker Compensator Systems

Function of a Compensator

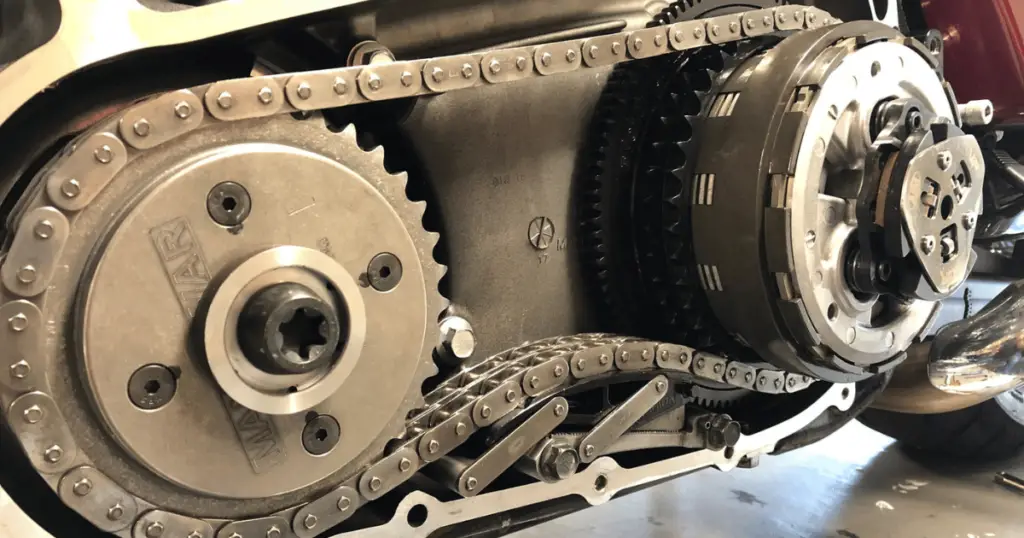

A compensator is a component of the Harley-Davidson primary drive system that reduces the impact of engine torque on the transmission and rear wheel. It does this by absorbing and releasing energy through a spring-loaded mechanism. The compensator is essential for a smooth ride and reduced wear on the transmission.

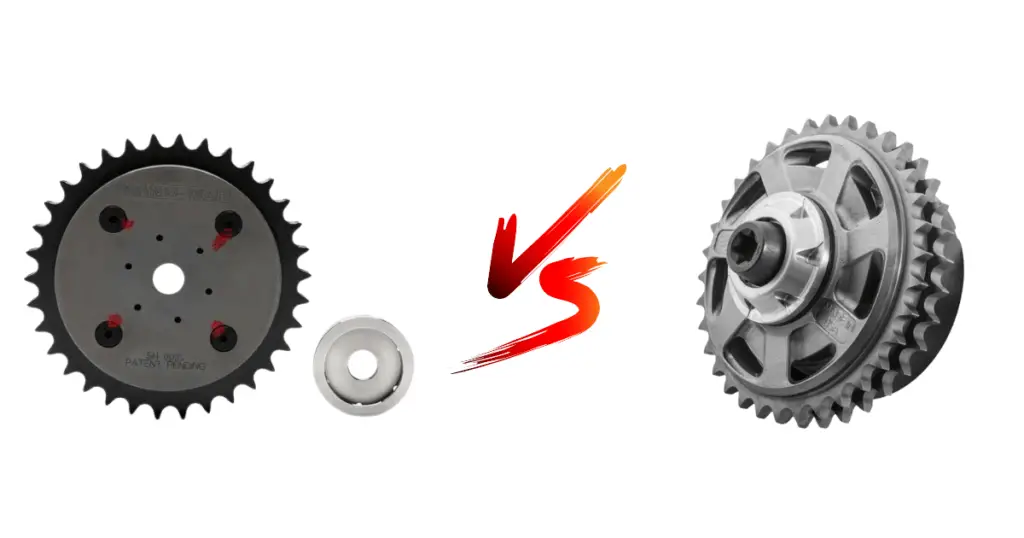

Baker Compensator vs. OEM

Baker Drivetrain is a company that specializes in producing high-performance drivetrain components for Harley-Davidson motorcycles. They offer a range of compensator systems that are designed to address the issues that are commonly found in OEM compensators.

One of the main differences between Baker compensators and OEM compensators is the design. Baker compensators are engineered to be stronger and more durable than OEM compensators. They are made with high-quality materials and are designed to withstand the stresses of high-performance riding.

Another difference between Baker compensators and OEM compensators is the level of customization. Baker compensators are available in a range of sizes and configurations, allowing riders to choose the perfect compensator for their specific needs. OEM compensators, on the other hand, are typically only available in one size and configuration.

Overall, the Baker compensator system is a reliable and high-performance option for Harley-Davidson riders who want to upgrade their primary drive system. With its superior design and customization options, the Baker compensator is a great choice for those who want to get the most out of their motorcycle.

Common Baker Compensator Problems

Baker compensators are high-quality products that are supposed to last for a long time. However, there are a few issues that users may face with these compensators. This section will discuss some of the common issues that users may face with Baker compensators.

Manufacturing Defects

One of the common issues with Baker compensators is manufacturing defects. Although Baker compensators are generally of high quality, there have been instances where manufacturing defects have caused problems. These defects can cause the compensator to fail prematurely, which can be costly to repair.

Wear and Tear

Another issue that users may face with Baker compensators is wear and tear. Over time, the compensator can wear out, which can cause it to fail. This can be due to a lack of lubrication or other factors. Regular maintenance can help prevent wear and tear on the compensator.

Oil Deflector Problems

Another issue that users may face with Baker compensators is oil deflector problems. The oil deflector is a component that helps keep oil from getting into the compensator. If the oil deflector fails, oil can get into the compensator and cause it to fail. Regular maintenance can help prevent oil deflector problems.

Lubrication Challenges

Finally, users may face lubrication challenges with Baker compensators. If the compensator is not properly lubricated, it can wear out prematurely. Regular maintenance can help ensure that the compensator is properly lubricated.

Otherwise, Baker compensators are generally of high quality, but users may face a few issues. Regular maintenance can help prevent these issues and ensure that the compensator lasts for a long time.

Maintenance and Troubleshooting

Regular Inspection

Regular inspection of the Baker compensator is crucial in identifying potential issues before they become major problems. It is recommended to inspect the compensator every 5,000 miles or during regular maintenance. During the inspection, the compensator sprocket and the primary chain tension should be checked for wear and damage.

Compensator Sprocket Issues

One of the most common issues with the Baker compensator is the disintegration of the mating surface of the compensator sprocket. This can cause significant damage to the primary chain and tensioner. If the compensator sprocket shows signs of wear or damage, it should be replaced immediately.

Primary Chain Tension Adjustments

Proper primary chain tension is essential for the smooth operation of the Baker compensator. If the tension is too loose, it can cause the chain to jump, leading to damage to the compensator sprocket. On the other hand, if the tension is too tight, it can cause excessive wear on the chain and the compensator sprocket. Regular adjustments to the primary chain tension should be made to ensure proper operation of the compensator.

It is also important to use the correct type and amount of primary oil. Using the wrong type of oil or insufficient oil can cause damage to the compensator and other components of the primary drive. It is recommended to use the oil specified by the manufacturer and to check the oil level regularly.

In summary, regular inspection, proper primary chain tension adjustments, and using the correct type and amount of primary oil are crucial in maintaining the Baker compensator. If any issues are detected, it is recommended to address them promptly to avoid further damage to the compensator and other components of the primary drive.

Upgrades and Replacement Solutions To Consider

If you are experiencing issues with your Harley Davidson compensator, upgrading to a high-quality Baker compensator kit might be the solution. Here are some things to consider when choosing and installing a Baker compensator kit.

Choosing a Baker Compensator Kit

Baker Drivetrain is a reputable company that specializes in manufacturing high-quality compensator kits. Their products are designed to improve starting ease, power delivery, throttle response, and overall bike performance.

When choosing a Baker compensator kit, it is important to make sure that it is compatible with your Harley Davidson model and year. You can consult with a trusted mechanic or do research online to find the right kit for your bike.

Installation Tips

Installing a Baker compensator kit can be a complex process, but with the right tools and instructions, it can be done at home. It is important to follow the manufacturer’s instructions carefully to ensure proper installation and avoid damaging your bike.

One important tip is to use a torque wrench to tighten the bolts to the recommended torque settings. This will help prevent over-tightening or under-tightening, which can cause issues with the compensator.

Adjustment and Shim Techniques

Once you have installed your Baker compensator kit, you might need to adjust and shim it to achieve optimal performance. This can be done by adding or removing shims to adjust the clearance between the compensator and the clutch basket.

It is important to follow the manufacturer’s instructions carefully when adjusting and shimming your compensator. Improper adjustment or shimming can cause issues with the compensator and other parts of your bike.

If you are unsure about how to adjust or shim your compensator, you can consult with a trusted mechanic or watch instructional videos on websites like Fix My Hog.

Overall, upgrading to a high-quality Baker compensator kit can be a great solution for Harley Davidson compensator problems. Just make sure to choose the right kit for your bike, follow the manufacturer’s instructions carefully, and adjust and shim your compensator as needed for optimal performance.

How Has Baker Addressed These Issues Over Time?

Baker’s Approach to Compensator Design

Baker Drivetrain is a well-known manufacturer of high-quality transmissions and drivetrain components for Harley Davidson motorcycles. The company has been in business for over 20 years, and during that time, they have developed a reputation for innovation and reliability.

One of the areas in which Baker Drivetrain has made significant advancements is in the design of compensators. The compensator is a critical component of the drivetrain, responsible for absorbing the shock and vibration that occurs during acceleration and deceleration.

Baker’s approach to compensator design is based on a deep understanding of the forces at play in the drivetrain. They have developed a compensator that is engineered to handle the stresses and strains of high-performance riding, while also providing a smooth and reliable ride.

Advancements in Compensator Technology

In recent years, Baker Drivetrain has made several advancements in compensator technology. One of the most significant is the development of an annular oil distribution system that scavenges primary oil and pumps it with centrifugal force to all radial and axial thrust surfaces. This system ensures that the compensator is adequately lubricated at all times, reducing wear and ensuring a long service life.

Another advancement is the use of high-strength materials in the construction of compensators. Baker compensators are made from high-grade steel, which provides exceptional strength and durability.

Baker Drivetrain’s commitment to innovation and quality is evident in their compensator designs. Their compensators are designed to provide a smooth and reliable ride, even under the most demanding conditions. Whether you ride a Softail or a Fat Boy, you can trust Baker Drivetrain to deliver the performance and reliability you need.