The Man O’ War compensator is an aftermarket part designed to replace the original equipment manufacturer’s (OEM) compensator in Harley Davidson motorcycles. It has become a popular solution for riders experiencing issues with the OEM part. The compensator is responsible for smoothing out engine torque fluctuations and reducing drive train lash, which in turn can enhance the riding experience by ensuring a smoother transition between gears and a more stable engine performance.

However, like any mechanical component, Man O’ War compensator problems can occasionally be encountered. Some riders have reported finding high levels of metal particles on their oil drain plug magnet, which can be indicative of abnormal wear and tear. This concern is often noticed during oil changes and can signal the need for closer inspection or replacement of the compensator. Issues can also manifest as unusual noises, such as rattling sounds at idle, which may indicate a problem with the compensator’s function.

Despite these concerns, many users report positive results with the Man O’ War compensator, noting a significant reduction in primary noise and smoother engagement of gears, particularly when shifting into first gear. By addressing the weak points in the stock setup, the Man O’ War compensator has been credited with enhancing the reliability and longevity of the motorcycle’s drivetrain. Nevertheless, it is essential for users to be aware of potential problems and to monitor their bikes for any signs of compensator malfunction.

Related read: Guide to Finding The Best Harley Compensator Upgrades Today

How Does A Compensator Work?

The compensator plays a critical role in motorcycle performance by buffering the shock between the engine and the drive components. It ensures a smooth transfer of power to the drivetrain and mitigates stresses that can cause wear.

Understanding Compensator Roles

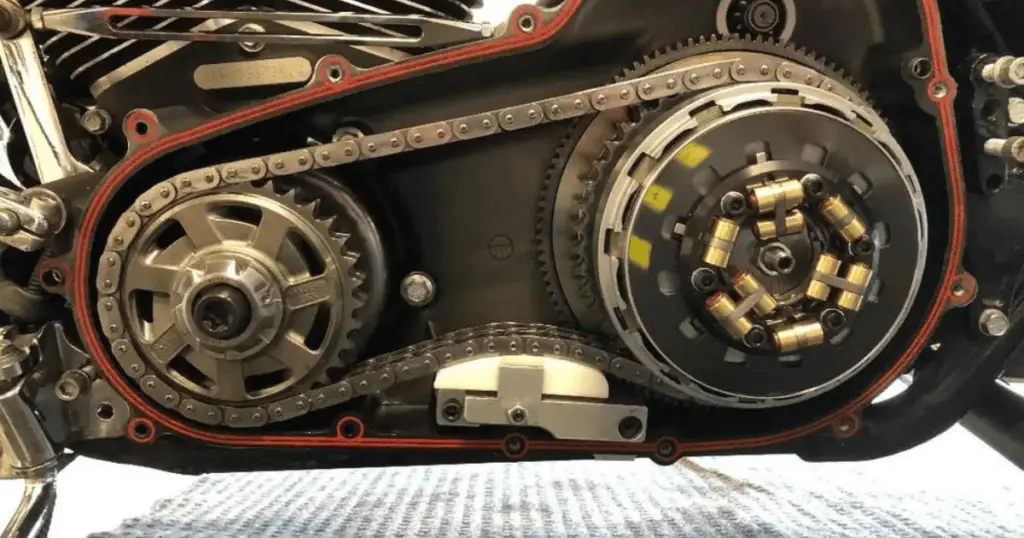

The compensator, often integrated with the sprocket, is a key component of a motorcycle’s primary drive system. Its primary role is to absorb and cushion the engine’s power pulses and torque fluctuations before they reach the chain and clutch assembly. This is crucial for maintaining consistent tension and prolonging the life of the drivetrain components.

- Compensator Sprocket: This component is directly connected to the engine’s output and works in unison with the clutch to manage power delivery.

- Tensioner: It maintains the required chain tension, preventing excessive slack that can lead to damage or erratic performance.

Common Man O’ War Compensator Problems

Compensator issues can lead to a variety of symptoms including increased primary noise and chain vibration.

- Noise: Often the first sign of compensator wear or failure is a Clunking or knocking noise emanating from the primary case, especially when shifting gears.

- Slack: Excessive slack in the chain due to a failing compensator can cause a jerky or unstable ride, as power transfer becomes less smooth.

Issues with the compensator sprocket can emerge from wear, resulting in poor engine to drivetrain power transfer and diminished ride quality. Regular inspection and maintenance are essential to identify and rectify such problems.

Overview of The Man O’ War Compensator

The Man O’ War compensator, designed as an upgrade for Harley Davidson motorcycles with a Twin Cam engine, addresses some limitations of the stock OEM compensator. This section explores the specific design attributes and benefits of the Man O’ War compensator and compares its features to the factory-installed OEM compensator.

Design and Benefits

- Improved Durability: The Man O’ War compensator typically offers enhanced durability compared to the OEM compensator. It is engineered to reduce wear and tear on engine components, potentially extending the longevity of the motorcycle’s drivetrain system.

- Smoother Operation: Riders often notice a smoother riding experience post installation. The compensator is designed to minimize noise and vibration, which contributes to a more comfortable and stable ride.

These features aim to elevate performance and reliability, making the Man O’ War a sought-after upgrade for many Harley enthusiasts.

How Does It Compare to An OEM Compensator?

- Design Features: While the OEM compensator is adequate for stock engine setups, the Man O’ War compensator often includes design improvements such as different tooth counts on the drive sprockets. For instance, whereas the OEM might have 34 teeth, the Man O’ War could have 32 teeth, altering the bike’s performance profile.

- Performance Impact: The Man O’ War compensator is reported to reduce primary noise, eliminate clunking when shifting into gear, and limit slack upon clutch release. These refinements tend to provide an advantage over the stock compensator, contributing to a more refined riding experience.

Overview of The Installation Process and Technical Specs

When installing a compensator, such as the Dark Horse Man-O-War, it’s vital to follow a precise, step-by-step process. This ensures proper fit and optimal control of the motorcycle’s cam chain adjuster.

Installation Process

The installation of the Man-O-War compensator requires careful attention to the manufacturer’s manual. The steps primarily involve:

- Removing the existing compensator assembly

- Aligning the new compensator with the sprocket shaft

- Securing the compensator as per the Dark Horse specifications for torque and fit

While the Dark Horse compensator comes with detailed guidelines, a basic mechanical proficiency is beneficial to ensure a smooth installation process. Technicians often note the importance of the correct alignment of components to prevent future complications.

Sprocket Shaft Runout Considerations

Sprocket shaft runout is a critical factor that must be addressed during the installation of any compensator. Here are specifics to consider:

- Maximum allowable runout: Typically, manufacturer specifications, such as those from Dark Horse, will denote maximum tolerances for sprocket shaft runout, critical for the longevity and functionality of the compensator.

- Measurement: Technicians should use a dial indicator to measure runout. A table can then document the readings to ensure they are within acceptable limits.

If the sprocket shaft runout exceeds the prescribed limit, it could lead to compensator issues, such as accelerated wear or operational noise. Maintaining the configuration within specifications helps in safeguarding the assembly against undue stress and potential failure.

Man O’War Compensator Problems and Reliability Overview

The Man O-War compensator has garnered mixed feedback regarding its reliability and performance in the context of Harley-Davidson motorcycles. Reports of both enhanced ride quality and durability concerns have been noted by users.

Wear and Durability

Wear: Some users have experienced increased wear on their motorcycle’s darkhorse flywheel crank assembly. This wear has often been attributed to the compensator adding extra weight on the end of the crankshaft, potentially affecting the bearings, connecting rods, and causing crank wear.

Durability: The debate on durability centers around observations of metal particles on oil drain plug magnets indicating potential internal damage. Concerns also extend to the drive sprocket, with changes from the OEM 34 tooth to the 32 tooth sprocket linked to these findings. Despite this, no widespread failure pattern has been conclusively documented.

How Does The Man O-War Improve Performance?

Improvements in Performance

Performance Enhancements: The Man O-War compensator claims improvements such as smoother shifts and a reduction in the “clunk” noise at low RPM, indicating a more balanced transmission of power. The use of a tuner may be recommended to optimize these benefits.

Rebuild Capacity: This compensator offers the potential for a rebuild, rather than replacement, which is an option not always available with OEM parts. Users considering performance-tuning their bikes have noted this as a value-added proposition.

In summary, the Man O-War compensator’s impact on reliability and performance presents a complex picture where rider experiences and the quality of installation play critical roles.

Troubleshooting and Maintenance Procedures

In maintaining the performance of a Man O’ War compensator, riders must become adept at troubleshooting issues and executing routine maintenance. This section provides a targeted approach to identifying common problems and offers essential tips to keep the compensator functioning optimally.

Identifying Compensator Issues

Noise: Unusual rattling or clunking sounds during idle or gear shifts could indicate issues within the compensator. It’s essential to listen for changes in the sound pattern, as these can be the first hint of complications.

Neutral Finding Difficulty: A compensator experiencing issues may cause a motorcycle to show resistance when being shifted into neutral. If engaging neutral becomes a challenge, this might point towards a compensator problem needing attention.

Clutch Basket Examination: Inspect the clutch basket for signs of abnormal wear or damage that may affect compensator function. A visual and physical inspection for deformities can prevent further problems.

Metal Particles in Oil: Upon oil inspection, the presence of metal particles on the drain plug magnet suggests internal wear and requires further investigation to pinpoint the cause, with a focus on the compensator’s integrity.

Chain Tensioner and Primary Chain Slop: The primary chain tensioner’s condition and any evident chain slop should be evaluated. Over time, a worn tensioner or excess slop can impose stress on a compensator, leading to premature wear.

Routine Maintenance Tips

Primary Case Oil Check: Regularly check and change the primary case oil, looking for metal particles that can indicate wear. Fresh oil helps ensure proper lubrication and cooling of moving parts.

Clutch Plate and Trans Inspection: Regular clutch plate inspection and maintenance can prevent excessive wear on the compensator. Making sure the clutch plates are in good condition and the transmission is functioning without issue helps maintain compensator health.

Chain Tensioner Inspection: Periodic inspection of the primary chain tensioner is critical to ensure adequate tension and stability of the chain, which in turn supports the compensator’s operation.

Shoe Inspection: The shoe, which comes in contact with the chain, should be checked for wear. Excessive wear on the shoe can lead to increased chain slop and strain on the compensator mechanism.

By following these troubleshooting and maintenance steps, riders can extend the lifespan of their Man O’ War compensator and ensure a smooth and reliable ride.

Frequently Asked Questions

In addressing common concerns, this section directly responds to some of the most frequently asked questions about compensator issues on Harley Davidson motorcycles, specifically focusing on the Man O War and comparable compensators.