Cub Cadet lawn tractors are known for their hydrostatic transmissions which provide a smooth ride and simple operation. However, like all machinery, these systems can encounter problems that affect their performance. Common Cub Cadet hydrostatic transmission problems include fluid leaks and loss of power, which can significantly impact the machine’s ability to operate efficiently.

Leaks in the hydrostatic transmission fluid are often the first sign of trouble. A decrease in fluid level can result in inadequate hydraulic pressure, leading to sluggish performance or an inability to move altogether. On the other hand, power loss or slow operation, especially when tackling hills or carrying heavy loads, can indicate internal wear or damage within the transmission system. Additionally, unusual noise during operation, such as grinding or whining, suggests there may be a problem with the transmission components. Identifying these signs early and addressing them is key to maintaining the tractor’s functionality and longevity.

Related problems:

– Cub Cadet Starter Problems: Quick Fixes, Tips and More

– Cub Cadet Carburetor Problems: Common Issues and Solutions

– Cub Cadet Ignition Switch Problems: Tips, Tricks, and More

– Cub Cadet Starting Problems: Quick Troubleshooting Guide

– Cub Cadet Starter Solenoid Problems: Causes and Solutions

– Cub Cadet Steering Problems: Causes and Solutions

Understanding The Hydrostatic Transmissions in Cub Cadet Mowers

Cub Cadet mowers utilize hydrostatic transmissions to provide a smooth drive and easy operation. This system relies on hydrostatic transmission fluid, a pump, and a motor to function effectively.

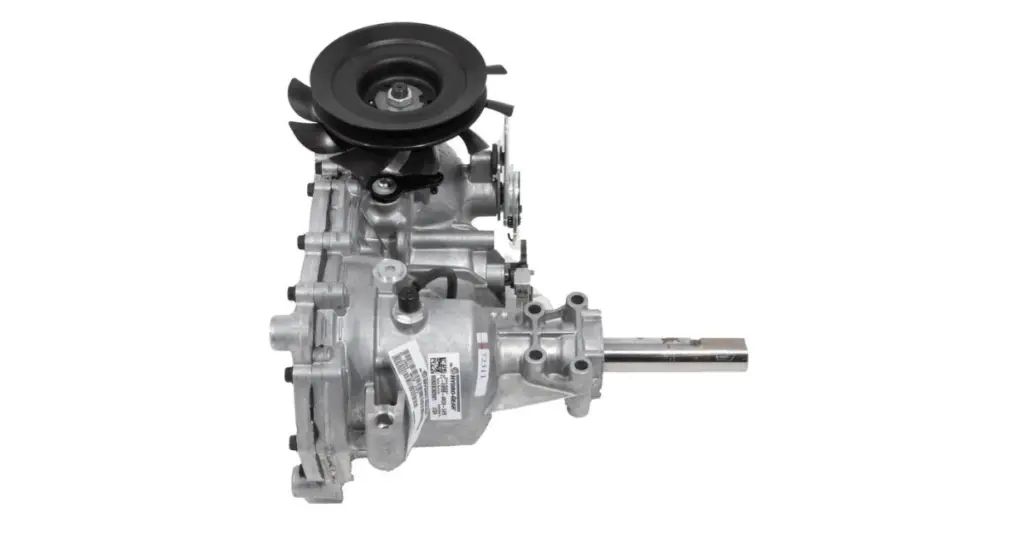

Components of Hydrostatic Transmission

Hydrostatic transmissions consist of several key components that work together to transfer power from the engine to the wheels. The heart of the system is a hydraulic pump which generates flow and pressure of the hydrostatic transmission fluid. This fluid is then conveyed to the drive motor, where it converts the fluid power into mechanical motion to drive the wheels. Proper maintenance of these components, especially the fluid levels and quality, is essential for the transmission’s longevity and optimal performance in Cub Cadet mowers.

- Pump: The component that generates fluid flow.

- Motor: Converts hydraulic power into mechanical.

- Hydrostatic Transmission Fluid: Provides the medium for power transfer.

Hydrostatic Transmission vs. Traditional Transmission

A hydrostatic transmission differs significantly from a traditional gear transmission. While a traditional transmission uses gears to change the speed and torque output, a hydrostatic transmission uses fluid dynamics.

- Hydrostatic Transmission

- Pros: Infinitely variable speed control, smoother operation.

- Cons: Requires strict maintenance, may exhibit problems like noise when clogged with debris.

- Traditional Transmission

- Pros: Simplicity, potentially longer lifespan with less maintenance.

- Cons: Limited speed settings, less smooth transitions.

The Cub Cadet hydrostatic transmission provides a seamless experience with fewer jerks and allows for precise speed control, a feature highly valuable when maneuvering around obstacles. However, this setup does necessitate careful attention to the state of the hydrostatic transmission fluid and adherence to maintenance schedules.

Regular Maintenance to Prevent Transmission Problems

Regular maintenance is essential in preventing hydrostatic transmission issues in Cub Cadet lawn mowers. Adhering to a maintenance schedule and performing fluid checks and changes can significantly reduce the risk of performance degradation and component failure.

Checking and Replacing Hydraulic Fluid

Hydraulic fluid is the lifeblood of the hydrostatic transmission. Owners should check the fluid level regularly and look for signs of contamination such as discolouration or the presence of debris. It is imperative to replace the hydraulic fluid according to the manufacturer’s recommendations, typically found in the mower’s manual, to ensure optimal performance and longevity of the transmission.

Maintaining Optimal Fluid Levels

Keeping the hydraulic fluid at the recommended level is critical. Fluid levels that are too low may lead to increased friction and wear, while levels that are too high can cause excessive pressure and leaks. Fluid levels should be monitored and adjusted if necessary after every 50 hours of use or at least annually.

Scheduled System Service and Purging

Over time, air can become trapped in the hydrostatic transmission system, leading to power loss and erratic operation. The system should be purged according to the service manual’s procedure to remove air and restore smooth operation. This process typically involves running the engine at full throttle with the motion control levers in neutral for a defined period, then repeating this process with the levers engaged. A complete system service, including purging, cleaning, and fluid changes, should be conducted at least once per season or after every 100 hours of operation to prevent fluid contamination and ensure reliable performance.

Troubleshooting Common Hydrostatic Transmission Problems

Proper troubleshooting of hydrostatic transmission problems in Cub Cadet equipment involves assessing symptoms such as loss of power, slipping, unusual noise, and overheating for timely corrections. Regular maintenance can help mitigate these issues; however, when they do arise, specific steps should be taken.

Dealing with Loss of Power and Slipping

When a Cub Cadet experiences a loss of power or slipping during operation, it could indicate hydraulic issues or a need for adjustment. It’s important to:

- Check the fluid level: Ensure the hydrostatic transmission fluid is at the correct level.

- Inspect drive belts: Worn or loose drive belts can cause slipping and loss of power.

Resolving Noise and Overheating Issues

Noise, such as grinding or whining from the Cub Cadet, typically signifies a deeper problem, potentially related to overheating:

- Clear debris from cooling fins: To prevent overheating, ensure that fins are clear from grass and other debris.

- Verify fan functionality: A Malfunctioning cooling fan can result in high temperatures and noise.

Fixing Leaks and Contamination

Leaking fluid and contamination can lead to serious hydrostatic transmission problems and should be addressed immediately. Steps include:

- Identify and seal leaks: Examine the transmission for leak points and replace damaged seals.

- Address air contamination: Bleed the system to remove air pockets that can lead to cavitation and transmission damage.

Specific Issues with Cub Cadet Models

Cub Cadet hydrostatic transmissions, particularly in the XT1 models and other riding mowers and lawn tractors, are known for specific operational challenges. These issues can impact performance and durability.

XT1 Hydrostatic Transmission Challenges

The XT1 series often encounters situations where the tractor exhibits insufficient power or erratic movement. Instances of fluid leakage can be a sign of compromised seals or gaskets within the hydrostatic transmission system, necessitating prompt inspection and repair. Moreover, owners have reported a phenomenon termed ‘creeping,’ which refers to the tractor inching forward or backward while in neutral, indicating potential transmission control rod misalignment.

- Leakage: Fluid leaks leading to low transmission fluid levels.

- Creeping: Movement while in neutral due to control rod misalignment.

Problems Unique to Riding Mowers and Lawn Tractors

Cub Cadet’s range of riding mowers and lawn tractors, beyond the XT1, also experience their own set of hydrostatic transmission problems. Air contamination of the hydraulic system and issues resulting from extreme temperatures causing the hydraulic system to overheat or function poorly in cold conditions are prominent. These temperature fluctuations can lead to a loss in fluid pressure and an increase in system temperature, affecting overall mower performance.

- Air Contamination: Air entering the hydraulic system leading to damage.

- Temperature Stress: Overheating or poor cold performance causing pressure loss and temperature rise.

Professional Expertise and When to Seek Help

When dealing with Cub Cadet hydrostatic transmission problems, homeowners may encounter issues that require a professional expert’s know-how. Recognizing the limitation of one’s skill set is critical in determining when to seek help.

Instances Where Expertise is Necessary:

- Persistent Noise: If the transmission emits continuous grinding or whining sounds despite basic troubleshooting.

- Loss of Power: When the mower struggles with climbing or hauling, beyond typical performance issues.

- Visible Damage: Noticing damaged parts upon inspection can indicate a need for professional repair.

Professionals bring a depth of experience and appropriate tools to fix intricate problems effectively. Their expertise is invaluable, particularly when the system shows signs of complex issues not resolvable with standard maintenance.

Benefits of Professional Assessment:

- Accurate Diagnostics: Experts can pinpoint the exact cause of transmission malfunctions.

- Specialized Tools: Repair requires specialized equipment that professionals readily possess.

- Warranty Maintenance: DIY repairs can sometimes void warranties; experts ensure compliance with warranty terms.

Homeowners should consider their ability to perform repairs against the potential cost of further damage. When in doubt, consulting a professional is the safest route to ensure the longevity and performance of the Cub Cadet hydrostatic transmission.

Frequently Asked Questions

Owners of Cub Cadet mowers often encounter various transmission issues. This section provides clear insights into the common questions they face and the steps they can take to address them.