Cub Cadet mowers are known for their reliability and performance, but like all mechanical equipment, they can experience starting problems. When a Cub Cadet mower fails to start, the issue can stem from several factors that prevent the engine from engaging. These issues may include a weak or discharged battery, which is a common culprit. A mower’s battery can run down when it sits idle for extended periods, especially over the winter months, and a weak battery will lack the necessary power to turn the engine over.

Troubleshooting Cub Cadet starting problems involves a systematic approach to diagnose and resolve issues. One frequent symptom of a starting problem is the sound of a clicking noise when the key is turned, which often points to a malfunctioning starter or starter solenoid. The starter solenoid acts as a bridge between the battery and the starter motor, and if it fails, the electrical charge necessary to start the engine doesn’t reach the starter. Beyond the electrical system, factors such as fuel quality, air intake, and spark plug condition also play critical roles in the engine starting process.

Maintenance plays a significant role in preventing starting problems with Cub Cadet mowers. It is important that users follow the starting procedures outlined in the operator’s manual and keep up with regular upkeep such as changing the spark plug, keeping the battery charged, and using fresh fuel. By addressing these key areas, many of the common Cub Cadet starter problems can be avoided or easily rectified. So what’re you waiting for? Let’s get to it!

Related issue:

– Cub Cadet Hydrostatic Transmission Problems (Complete Guide)

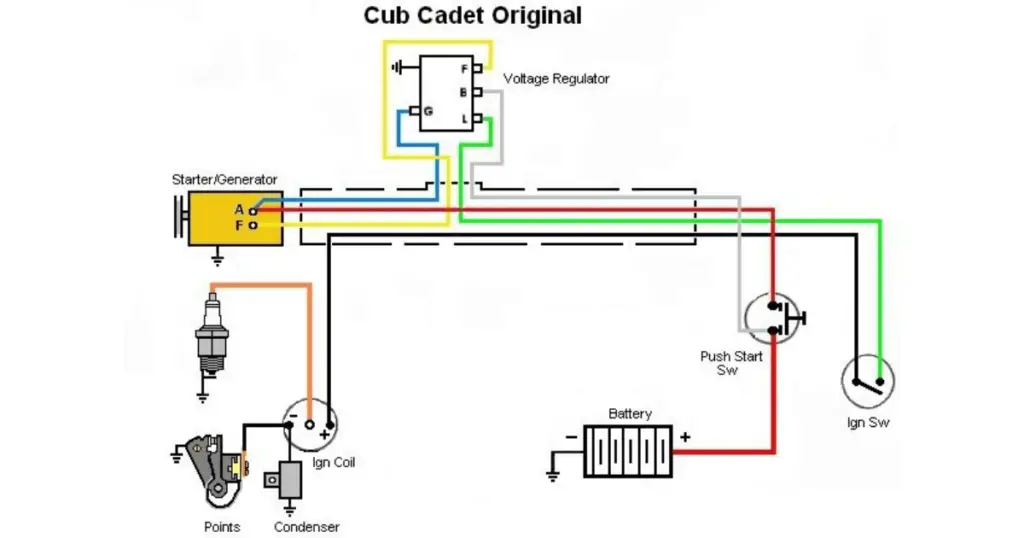

Understanding the Starter System

A well-functioning starter system is crucial for reliable operation of a Cub Cadet mower. This section breaks down its key components and operation.

What Are The Components of the Starter System?

- Starter Motor: An electric motor that initiates engine operation.

- Cub Cadet Starter Solenoid: A relay that safely connects the starter motor to the battery.

- Battery: Provides the necessary electrical power to the starter motor.

- Ignition Switch: Activates the starter system when turned.

Safety features and precautions are in place to prevent accidental starts and ensure safe operation.

How Does The Starter System Work?

When the ignition switch is turned, an electrical signal is sent to the starter solenoid. This solenoid then closes the circuit between the battery and starter motor. The starter motor engages the engine, beginning the starting procedure. Safety features ensure that the mower only starts under safe conditions.

What Are The Most Common Starting Problems and Solutions?

Cub Cadet mowers may experience starting issues due to a range of problems from battery failures to airflow disruptions. This section covers troubleshooting steps and solutions for the most common starting problems encountered by owners.

Battery Issues

Weak or Dead Battery: A mower that fails to start often has a battery problem. A dead battery is unable to turn the engine over, while a weak battery may result in slow cranking. To resolve this:

- Check for corrosion on the battery terminals; clean with a baking soda solution if necessary.

- Verify the charging system is functioning correctly to ensure the battery can hold a charge.

Fuel System Complications

Bad or Old Fuel: Fuel problems such as old gas with too much ethanol can deteriorate and clog the fuel system. Recommendations include:

- Replace old gas with fresh fuel and use a fuel stabilizer to prevent future issues.

- Inspect and replace clogged fuel filters, ensure fuel lines are clear, and check the fuel pump and fuel tank cap for proper operation.

Ignition Troubles

Faulty Spark Plug: A bad spark is a common culprit for starting issues. If the spark plug is damaged or loose, the engine might not start. To fix:

- Clean or replace spark plugs as needed to ensure they produce a proper spark.

- Check the ignition coil for signs of wear or malfunction and replace if necessary.

Air Flow Disruptions

Clogged Air Filter: Restricted airflow can prevent an engine from starting. The choke mechanism also plays a role in airflow management when starting the engine. To address these issues:

- Replace a dirty or clogged air filter to improve airflow.

- Make sure the choke is functioning properly and adjust if needed.

Electrical and Connection Troubleshooting

Diagnosing electrical issues in Cub Cadet machines requires systematic testing of electrical components and thorough inspection of all connections. Proper use of a multimeter and attention to connection integrity can resolve problems that prevent the mower from starting.

Testing Electrical Components

Battery Voltage: To assess if the battery is supplying sufficient power to start the engine, one should use a multimeter. Set the multimeter to the appropriate voltage range and touch the probes to the corresponding terminals—red to positive and black to negative. A healthy battery should read around 12.6 volts when fully charged.

- Safety Switch: A malfunctioning safety switch can interrupt the starting sequence. One must test each safety switch with the multimeter for continuity to ensure it operates correctly. Common safety switches to check include those for the seat, clutch, and parking brake.

Addressing Connection Issues

Electrical Connections and Terminals: Each electrical connection should be inspected for cleanliness and security. Corrosion or a bad connection at the terminals can lead to starting issues.

- Clean any corrosion from the terminals with a wire brush and check for a tight fit.

- Ensure the positive cable, along with all other cables, are securely attached and not showing signs of wear.

Loose Connections: A loose connection can result in intermittent power supply issues. Tightening all connections, especially the main wiring harness and solenoid connections, is fundamental. Use care not to over-tighten and damage the terminals.

- A visual inspection should reveal any loose connections. If a connection appears loose, secure it and check for improvements in starting performance.

Regular maintenance of electrical components and connections is crucial for the longevity and reliability of Cub Cadet machines.

Maintenance Tips to Avoid Starter Problems

Proper maintenance is imperative to mitigate starter issues in Cub Cadet lawn mowers, including the Cub Cadet XT1. This section provides specific actions you can take within two critical domain areas: Regular Inspection and Cleaning, and Fuel Management, to ensure reliable operation and longevity of your riding mower or lawn tractor.

Regular Inspection and Cleaning

It is crucial for an owner to regularly inspect and clean their Cub Cadet’s starting system to avoid common starting problems.

Spark Plug:

- Check the spark plug every 25 hours of use or once a season.

- If it’s soiled or damaged, it should be cleaned or replaced. A clean spark plug ensures efficient ignition.

Air Filter:

- Inspect the air filter every 25 hours or at the beginning of the mowing season.

- Cleaning or replacing a clogged air filter can prevent starting issues, as a clean filter allows for proper air flow to the engine.

Debris Removal:

- Keep the mower’s engine area free of debris.

- Grass clippings, leaves, and dirt can accumulate and affect the starter components.

Fuel Management

Managing the fuel system is also essential for preventing starter problems in Cub Cadet mowers.

Fuel Quality:

- Always use fresh gasoline with a minimum octane rating of 87 and a maximum of 10% ethanol content.

- Old or low-quality fuel can lead to starting difficulties.

Fuel Additives:

- Utilize a fuel stabilizer if the mower will not be used for over a month.

- Adding stabilizer to the fuel can prevent the degradation of gasoline and ensure the fuel system remains clean.

Fuel System Inspection:

- Periodically inspect the fuel lines and filter for clogs or damage.

- A well-maintained fuel system ensures that gasoline flows correctly to the engine, vital for easy starting.

By adhering to these maintenance tips, one can greatly reduce the risk of encountering starter problems with their Cub Cadet lawn mowers.

When Should You See A Professional?

When a Cub Cadet mower doesn’t start, it often can be attributed to common starter problems. These issues may manifest as a troubling click or hum on ignition, indicating potential starter motor issues. Understanding when to seek professional help and evaluating repair costs are crucial in addressing these frustrations effectively.

When to Seek Professional Help

Symptoms Indicating Professional Assistance is Required:

- The mower produces a clicking sound but fails to start.

- The starter motor operates but the engine does not engage.

- There is a complete lack of sound or action when the key is turned.

Common Starter Problems that Warrant a Repair Service:

- A battery that is too weak to turn the starter.

- A broken starter worm shaft.

- Faulty spark plugs unable to initiate combustion.

- Starter gear engagement issues.

These specific symptoms often require a specialist’s knowledge to diagnose and fix effectively. If the Cub Cadet mower exhibits any of these issues, owners should consider consulting a professional to avoid further damage and ensure a safe and accurate repair.

DIY vs Professional Repair Costs

Factors Influencing Repair Costs:

- Severity of the Issue: A simple battery replacement will cost less than a broken starter motor.

- Parts: The cost of replacement starter motors or solenoids may vary.

- Labor: Hourly rates for a professional mechanic can add up depending on the complexity of the repair.

| Repair Approach | Estimated Cost Range |

|---|---|

| DIY Repair | $20 – $200 (for parts) |

| Professional | $100 – $400 (parts and labor) |

The decision to attempt a DIY repair or to hire a professional should be made after considering both the owner’s technical skill level and the potential cost savings. While DIY can be more cost-effective, it carries the risk of incorrect installation or diagnosis. Conversely, professional repairs offer expertise and often come with a warranty, providing a guarantee of the work performed.

Frequently Asked Questions

When dealing with Cub Cadet starter problems, owners often have questions about maintenance and troubleshooting. This section addresses some of the most common queries related to the Cub Cadet XT1 and LT1050 models, focusing on the starter system components and their servicing.