When troubleshooting John Deere S100 issues, imagine unraveling a mystery within your machine. As you set off on this journey of diagnostics and problem-solving, each component holds a clue waiting to be discovered. From the engine's heartbeat to the electrical system's pulse, and the transmission's shifting whispers, there are tales to uncover in each part of your equipment. Stay tuned as we navigate through common problems and solutions, equipping you with the knowledge to crack the code of your John Deere S100's malfunctions.

Things to Note

- Check fuel and oil levels, inspect for contaminants.

- Ensure essential fluids are present.

- Examine air filter for dirt or clogs.

- Address unusual noises or vibrations promptly.

- Consult the technical manual for complex issues.

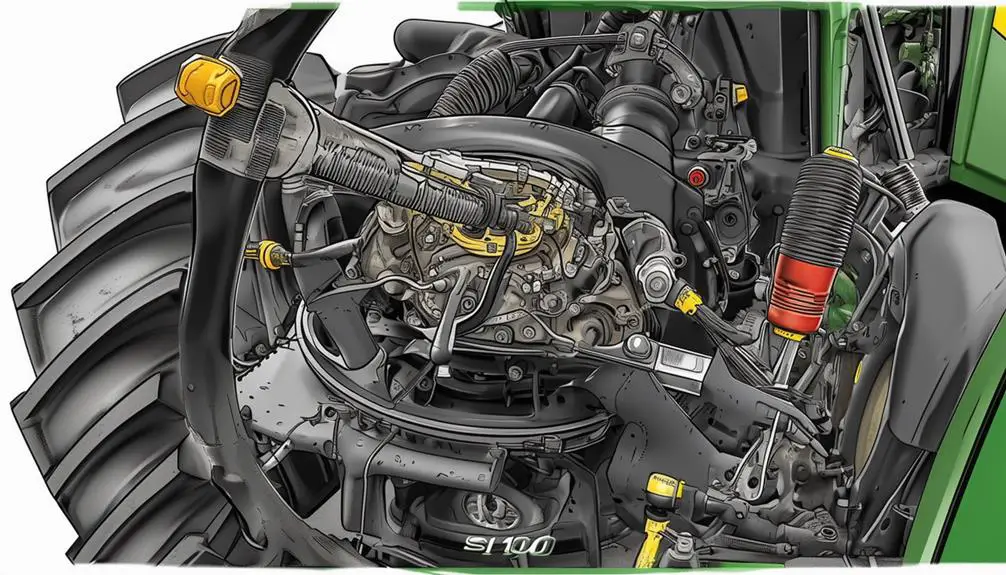

Common Engine Issues

If your John Deere S100 is experiencing common engine issues, start by checking the fuel and oil levels before attempting any troubleshooting. Sometimes, the simplest solutions can solve the most frustrating problems. Make sure your machine is well-equipped with the essential fluids it needs to run smoothly. Additionally, inspect the fuel tank for any contaminants or debris that could be clogging the system.

Next, take a look at the air filter. A dirty air filter can hinder engine performance and lead to issues like poor acceleration or rough idling. Changing the air filter regularly can notably improve your John Deere S100's overall health.

In addition to basic maintenance checks, pay attention to unusual noises or vibrations coming from the engine. These could be signs of more serious problems that require professional attention. By staying proactive and addressing issues promptly, you can keep your John Deere S100 running smoothly and efficiently for years to come.

Electrical System Troubleshooting

Check the electrical system of your John Deere S100 to troubleshoot any potential issues that may be affecting its performance.

When dealing with electrical problems, it's crucial to approach the situation with a sense of empowerment. Here are some steps to help you liberate your John Deere S100 from electrical troubles:

- Inspect the Battery Connections: Verify the battery cables are securely connected to avoid power interruptions.

- Test the Alternator Output: Confirm that the alternator is supplying adequate power to the electrical system.

- Check the Fuses: A blown fuse can cause electrical components to malfunction.

- Examine the Wiring: Look for any frayed or damaged wires that could be causing a short circuit.

- Assess the Ground Connections: Inadequate grounding can lead to various electrical issues.

Addressing Transmission Problems

To effectively resolve issues associated with the transmission of your John Deere S100, a systematic approach to diagnostics and troubleshooting is crucial. When facing transmission problems, start by checking the transmission fluid level and condition.

Low fluid levels or dirty fluid can lead to issues with gear shifting and overall performance. Confirm that the transmission filter is clean and not clogged, as this can hinder the flow of fluid and cause transmission problems as well.

Additionally, inspect the transmission belts for any signs of wear or damage, as worn-out belts can affect the transmission's ability to function properly. If these basic checks don't uncover the source of the problem, it may be necessary to consult the technical manual for further guidance or seek assistance from a qualified technician.

Hydraulic System Faults

When dealing with hydraulic system faults on your John Deere S100, start by checking for fluid leaks to pinpoint potential issues.

Next, diagnose the pump for any malfunctions that could be affecting the system's performance.

Fluid Leak Detection

Scan the hydraulic system for any telltale signs of fluid leaks to pinpoint potential faults in your John Deere S100. Checking for fluid leaks is essential as they can indicate underlying issues that need immediate attention.

Here's how you can detect fluid leaks and take charge of your troubleshooting process:

- Look for puddles or drips: Keep an eye out for any puddles or drips underneath your equipment.

- Inspect hydraulic hoses: Check the hydraulic hoses for any visible cracks, abrasions, or bulges.

- Examine fittings and connectors: Confirm all fittings and connectors are securely fastened without any signs of leakage.

- Monitor fluid levels: Regularly check the hydraulic fluid levels to spot any sudden drops that may indicate a leak.

- Use a UV dye: Consider adding a UV dye in the hydraulic system to easily trace the source of any leaks under UV light.

Pump Malfunction Diagnosis

How can you identify potential pump malfunctions within the hydraulic system of your John Deere S100?

One common sign of a pump malfunction is if you notice a decrease in the speed or power of your equipment. When operating your S100, pay attention to any unusual noises coming from the hydraulic system, such as whining or grinding sounds, as these can indicate pump issues.

Additionally, if you experience erratic or jerky movements when using the controls, it could be a sign that the pump isn't functioning correctly.

To further diagnose a pump malfunction, check the hydraulic fluid level and quality. Low fluid levels or dirty fluid can put a strain on the pump and lead to malfunctions.

Inspect the pump for any visible signs of leaks or damage. If you suspect a pump issue, it's essential to address it promptly to avoid further damage to your John Deere S100's hydraulic system.

Hose Integrity Check

To secure the proper functioning of your John Deere S100's hydraulic system, regularly inspect the integrity of the hoses for potential faults. Checking the hoses for any signs of wear, leaks, or damage is essential in maintaining the efficiency of your equipment.

Here are some tips to help you verify the hoses are in top condition:

- Visual Inspection: Look for cracks, bulges, or abrasions on the hoses.

- Flexibility Test: Gently bend the hoses to check for any stiffness or brittleness.

- Leak Detection: Examine for any oil or fluid leaks along the hose connections.

- Secure Fittings: Confirm all fittings are tightly secured to prevent any leaks.

- Replace When Needed: Don't hesitate to replace any hoses showing signs of wear or damage.

Cooling System Solutions

Let's address the cooling system solutions for your John Deere S100.

Confirm the cooling fan is operating correctly.

Inspect the radiator for any issues.

Don't forget to regularly check the coolant level.

These simple steps can help prevent overheating and keep your equipment running smoothly.

Cooling Fan Operation

Ensure the cooling fan on your John Deere S100 is working properly to prevent overheating issues. A properly functioning cooling fan is essential for maintaining optimal engine temperature, especially during long hours of operation.

Here are some essential tips to guarantee your cooling fan is operating efficiently:

- Regular Inspection: Take the time to inspect the cooling fan regularly for any signs of damage or wear.

- Cleanliness Is Key: Keep the cooling fan and surrounding area clean from dirt and debris that could obstruct its operation.

- Listen Carefully: When starting your John Deere S100, listen for any unusual noises coming from the cooling fan that might indicate a problem.

- Check Connections: Ensure that all connections to the cooling fan are secure and free from corrosion.

- Monitor Temperature: Keep an eye on the temperature gauge while operating the equipment to detect any sudden spikes that could point to cooling fan issues.

Radiator Inspection Tips

Regularly checking the radiator is vital for ensuring peak performance of your John Deere S100's cooling system. To begin, visually inspect the radiator for any signs of damage such as leaks, corrosion, or bent fins. These issues can lead to inefficient cooling and potential overheating problems.

Next, make sure the radiator is clean and free from any debris or buildup that could obstruct airflow. Use a soft brush or compressed air to gently remove dirt and dust from the radiator fins.

Additionally, inspect the radiator hoses for any cracks, leaks, or loose connections that may affect the coolant flow. It's also important to verify that the radiator cap is in good condition and sealing properly to maintain the correct pressure in the cooling system.

Coolant Level Check

Examining the coolant level in your John Deere S100 is crucial for maintaining peak cooling system performance. To maximize your machine runs smoothly, follow these simple steps:

- Check the coolant level when the engine is cool: Avoid burns and accurately assess the coolant level.

- Use the proper coolant mixture: Best performance requires the right coolant concentration.

- Look for any signs of coolant leaks: Addressing leaks promptly can prevent major issues down the road.

- Top up coolant as needed: Keep your cooling system functioning at its best by maintaining the proper coolant level.

- Regularly inspect hoses and connections: Ensuring all components are secure and in good condition can prevent unexpected cooling system failures.

Dealing With Fuel Problems

Facing fuel issues with your John Deere S100? Here's how to tackle them head-on.

Start by checking the fuel level in the tank to make sure it's sufficient for operation. If the level is low, refill with clean, fresh fuel to prevent any clogs or engine misfires.

Next, inspect the fuel lines for any signs of damage, leaks, or blockages that could be hindering the flow of fuel to the engine. Replace any faulty fuel lines promptly to maintain peak performance.

Additionally, it's essential to clean or replace the fuel filter regularly to prevent contaminants from entering the engine. A clogged fuel filter can lead to engine stalling or rough idling.

Tackling Steering and Brakes Issues

To address steering and brakes issues with your John Deere S100, start by inspecting the components for any signs of wear or damage. Here are some steps to help you tackle these problems:

- Check for loose bolts or connections: Tighten any loose bolts or connections to ensure proper functioning.

- Inspect brake pads: Look for wear and tear on the brake pads and replace them if necessary for peak braking performance.

- Examine steering linkage: Ensure the steering linkage isn't bent or damaged, affecting your ability to steer smoothly.

- Verify brake fluid levels: Make sure the brake fluid levels are adequate to maintain proper brake function.

- Test the brakes and steering: Take your John Deere S100 for a test drive to assess if the issues have been resolved.

Identifying Belt and Pulley Concerns

Inspect the belt and pulley system on your John Deere S100 for any signs of wear or misalignment that may be affecting performance.

Begin by visually examining the belts for cracks, fraying, or any shiny spots that indicate excessive wear. Check the tension of the belts by pressing down on them; they should give a little but not feel loose.

Verify the pulleys are properly aligned and not wobbling when the engine is running. Look for any debris or residue that could be interfering with the belts' movement.

If you notice any issues, such as squealing noises or the belts slipping, it's important to address them promptly to prevent further damage. Regularly cleaning and inspecting the belt and pulley system can help maintain peak performance and prevent unexpected breakdowns.

Troubleshooting Error Codes

When troubleshooting error codes on your John Deere S100, start by referencing the owner's manual for specific guidance on interpreting and resolving the codes. Error codes can be frustrating, but with the right approach, you can quickly get back to work.

Here are some tips to help you navigate through this process:

- Stay Calm: Keeping a clear mind will help you focus on the issue at hand without getting overwhelmed.

- Check Connections: Verify all connections are secure and free of debris that could be causing communication errors.

- Update Software: Sometimes a simple software update can resolve error code issues, so make sure your system is up to date.

- Inspect Sensors: Faulty sensors can trigger error codes, so a thorough inspection can help identify any problematic sensors.

- Consult Online Resources: Online forums and resources can provide valuable insights from others who've experienced similar error codes.

Frequently Asked Questions

How Often Should I Change the Oil in My John Deere S100?

You should change the oil in your John Deere S100 every 100 hours of use or at least once a year.

Regular oil changes help maintain the engine's performance and extend its lifespan.

Don't forget this simple maintenance task to keep your equipment running smoothly.

Can I Use Aftermarket Parts for Repairs on My John Deere S100?

Just like a painter chooses colors, you have the freedom to opt for aftermarket parts for your John Deere S100 repairs.

While some purists may argue authenticity, aftermarket parts can offer cost-effective alternatives without compromising quality.

Confirm compatibility and quality standards to keep your John Deere running smoothly.

Embrace the power of choice when it comes to maintaining your equipment.

What Is the Recommended Tire Pressure for the John Deere S100?

To maintain peak performance, keep your John Deere S100's tires properly inflated. The recommended tire pressure for the John Deere S100 is vital for safety and efficiency.

Make sure to check and adjust the tire pressure regularly to meet the manufacturer's guidelines. Following these suggestions will help you maintain traction, stability, and overall performance while operating your John Deere S100 smoothly.

How Do I Properly Store My John Deere S100 During the Off-Season?

When storing your John Deere S100 during the off-season, remember the saying 'A stitch in time saves nine.'

To properly store it, clean the machine thoroughly, change the oil, grease moving parts, and remove the battery.

Store it in a dry, covered area to protect it from the elements.

Are There Any Software Updates Available for the John Deere S100?

Yes, there are software updates available for the John Deere S100.

To check for updates, visit the official John Deere website and navigate to the support section.

From there, you can easily find and download any available software updates for your S100 model.

Regularly updating your equipment's software promotes peak performance and can help address any potential issues or bugs.

Conclusion

To sum up, troubleshooting John Deere S100 problems may seem challenging, but with the right approach, it can be a smooth process.

Remember to stay patient and focused when addressing any issues that may arise.

By following these steps and staying proactive, you'll be able to keep your equipment running smoothly and efficiently.

Happy troubleshooting!