When it comes to motorcycle maintenance, understanding torque specs isn't just a technical detail; it's crucial for your bike's performance and safety. You might think consulting your service manual is enough, but there are nuances that can make a big difference. Using a properly calibrated torque wrench is essential, and so is knowing the right tightening sequence. Plus, different materials demand specific torque settings, which many overlook. As you explore these tips, you'll uncover how even minor mistakes can lead to significant consequences for your ride. What's the first mistake most people make?

Key Takeaways

- Always refer to the motorcycle's service manual for accurate torque specifications specific to your model.

- Use a quality torque wrench to ensure precise torque application; digital or beam-type options are available.

- Understand the proper tightening sequence to avoid warping components and ensure even pressure distribution.

- Regularly calibrate your torque wrench to maintain accuracy and prevent under-torquing or over-torquing.

Importance of Torque Specs

Understanding the importance of torque specs is essential for ensuring your motorcycle's performance and safety. You mightn't realize it, but every bolt and nut on your bike has a specific torque requirement. When you adhere to these specifications, you're not just tightening components; you're creating a harmonious relationship between every part of your machine.

Over-tightening can lead to stripped threads or even component failure, while under-tightening can result in dangerous vibrations or disconnections. By following the correct torque specs, you empower yourself to maintain the bike effectively, enhancing its reliability and longevity. You're taking control of your ride, ensuring that it can handle the twists and turns of the open road without the fear of mechanical failure.

This knowledge liberates you from depending solely on mechanics, allowing you to embrace the thrill of self-sufficiency. Every adjustment you make becomes an opportunity for growth, deepening your connection to your motorcycle. By understanding torque specs, you're not just a rider; you're a steward of your machine, fostering a relationship built on trust and precision.

Ducati Torque Specifications Overview

When working on your Ducati, knowing the specific torque specifications for various components is essential for guaranteeing ideal performance and safety. These specs aren't just numbers; they're the key to releasing the full potential of your ride.

From the engine to the chassis, each bolt and nut has a designated torque that can make all the difference. For instance, when tightening the cylinder head bolts, you'll want to follow the manufacturer's specifications closely. Over-torquing can lead to warping, while under-torquing might cause leaks or catastrophic failure.

Similarly, the wheel axle nuts require precise torque to maintain stability and guarantee safety during high-speed rides. Don't forget about the brake calipers; they need specific torque settings to keep them functioning at their best. If you ignore these details, you might compromise your bike's performance and, worse, your safety.

Always consult your Ducati's service manual for the exact figures. Embracing these specifications means you're not just a rider; you're a skilled craftsman, liberating the power of your machine on the open road.

Stay informed, stay safe, and enjoy every ride to its fullest!

Tools for Measuring Torque

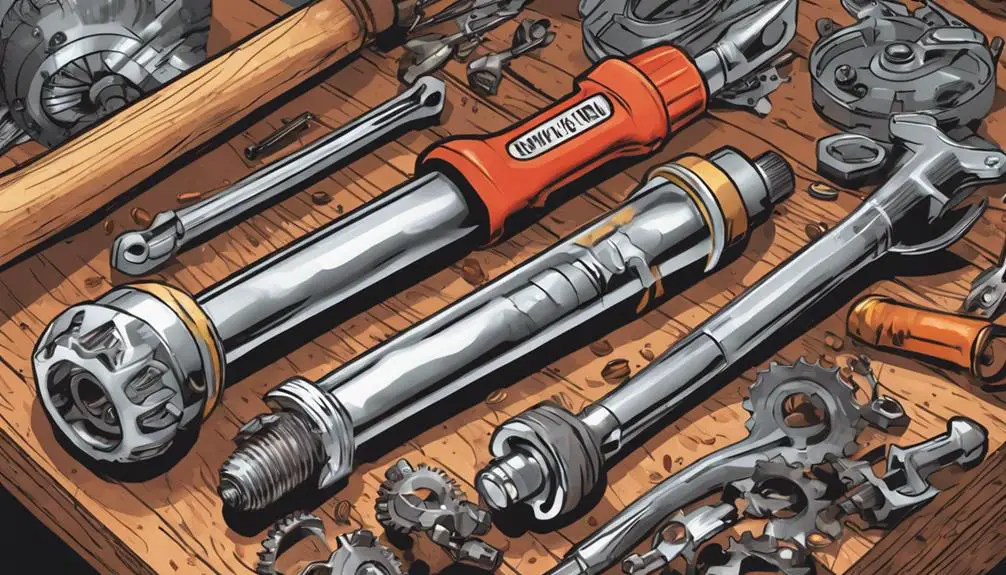

To guarantee accurate torque application, you'll need specific tools designed for measuring torque effectively. Using the right tools empowers you to maintain your motorcycle's performance and safety.

Here's a list of essential tools you should consider:

- Torque Wrench: This is your primary tool for applying precise torque. Digital or beam-type options help you achieve accurate results.

- Torque Adapter: If you're using a standard wrench, a torque adapter can convert it into a torque wrench, making it versatile for various jobs.

- Torque Angle Gauge: For tasks requiring angle tightening, this tool measures rotational degrees, assuring you get it just right.

- Socket Set: A good set of sockets in different sizes ensures you can tackle any bolt on your bike, and when combined with a torque wrench, it makes the job easier.

Common Torque Mistakes

Many motorcycle enthusiasts make common torque mistakes that can lead to performance issues or safety hazards. One of the biggest errors is under-torquing or over-torquing fasteners. You might think a little extra torque will keep things tighter, but that can strip threads or damage components. Always stick to the manufacturer's specifications.

Another mistake is skipping the proper sequence when tightening bolts. If you rush and don't follow the specified pattern, you risk warping parts or creating uneven pressure. Take your time, and use the right sequence to guarantee everything fits snugly.

Not using a calibrated torque wrench is another pitfall. Relying on guesswork or a cheap tool can spell disaster. Make certain your wrench is set correctly and check its calibration regularly.

Lastly, don't forget to reflect on the material and condition of the components you're working with. Different materials require different torque settings. Always double-check the specs based on the parts you're dealing with.

Maintaining Performance With Specs

Maintaining your motorcycle's performance hinges on adhering to the manufacturer's torque specifications for every component. When you respect these specs, you not only guarantee safety but also enhance your ride's freedom and responsiveness.

Here are four vital tips to keep your motorcycle performing at its peak:

- Consult the Manual: Always refer to your motorcycle's service manual for exact torque specs. It's your roadmap to peak performance.

- Use a Torque Wrench: Invest in a quality torque wrench. This tool helps you achieve precise torque, preventing over-tightening or under-tightening.

- Check Regularly: Make it a habit to check torque specs periodically, especially after major rides or repairs. Components can loosen over time, and staying vigilant keeps your ride smooth.

- Understand Component Importance: Recognize that each component plays a significant role. From the engine to the wheels, proper torque guarantees everything works harmoniously for that exhilarating ride you crave.

Frequently Asked Questions

How Often Should I Check My Motorcycle's Torque Specs?

You should check your motorcycle's torque specs regularly, ideally every time you perform maintenance or make adjustments. This helps guarantee safety and performance.

Don't wait until something feels off; being proactive keeps your ride smooth and reliable. If you're hitting the road frequently, consider checking them every few weeks.

Can I Use a Regular Wrench Instead of a Torque Wrench?

You might think a regular wrench could do the job, but can it really?

Torque is all about precision, and without that, you're risking more than just a loose bolt.

A torque wrench gives you the control you crave, ensuring everything's just right.

Imagine the freedom of knowing your bike's safe and sound, ready to take you wherever you desire.

Don't settle for less when you can have the confidence that comes with proper torque!

What Happens if I Exceed Torque Specifications?

If you exceed torque specifications, you risk damaging components or causing failure.

Over-tightening can strip threads, crack parts, or create uneven pressure, leading to performance issues. You might also find that seals fail, causing leaks.

This could compromise your vehicle's safety and reliability.

So, it's essential to respect those specifications to maintain the integrity of your ride and guarantee everything functions smoothly.

Trust the numbers, and your machine will thank you!

Are Torque Specs the Same for All Motorcycle Brands?

No, torque specs aren't the same for all motorcycle brands. Each manufacturer designs their bikes with unique engineering standards, which means the required torque can vary considerably.

You'll want to consult your bike's service manual for the specific torque values. Adhering to these specs guarantees your ride performs at its best and keeps you safe on the road.

Understanding your bike's needs empowers you to maintain it effectively and ride with confidence.

Do Temperature Changes Affect Torque Specifications?

Temperature changes can twist your perceptions of torque specs like a wild ride on a winding road.

As temperatures rise or fall, the materials in your motorcycle expand or contract, which can affect how tight your bolts need to be.

It's vital to factor in these changes, especially when you're gearing up for an adventure.

Adjusting for temperature guarantees your bike stays safe and performs at its best, giving you the freedom to ride without worry.

Conclusion

In the world of motorcycle maintenance, torque specs are your guiding compass. Just as a well-tuned engine hums in harmony, adhering to these specifications guarantees your ride operates smoothly and safely.

By treating your bike with the care it deserves—like a trusted companion on the open road—you not only enhance its performance but also prolong its life.

Remember, every bolt tightened correctly is a step towards adventure, keeping you and your motorcycle in perfect sync.