You might not realize that the right hydraulic fluid can greatly extend the lifespan of your John Deere 333G. Choosing a high-quality hydraulic fluid isn't just about performance; it also affects the overall efficiency and reliability of your machinery. By understanding which fluids best suit your equipment, you can guarantee ideal operation under various conditions. So, what are the top hydraulic fluids that experts recommend for your John Deere 333G? Let's explore the options that can enhance your machine's performance and longevity.

Quick Takeaways

- TRIAX Atros MV HVLP offers superior anti-wear protection and operates effectively from -54°F to 150°F for optimal performance.

- Star Fire Premium AW 46 excels in thermal stability and wear protection, ensuring consistent operation in high-temperature conditions.

- TRIAX Agra UTTO XL boasts a 6,000-hour oil life, reducing fluid change frequency and ensuring compatibility with various farming equipment.

- Choosing the correct viscosity grade is crucial for preventing cavitation and ensuring reliable performance in the John Deere 333G.

- Fluids must meet John Deere specifications for warranty compliance and optimal performance, emphasizing the importance of additive packages.

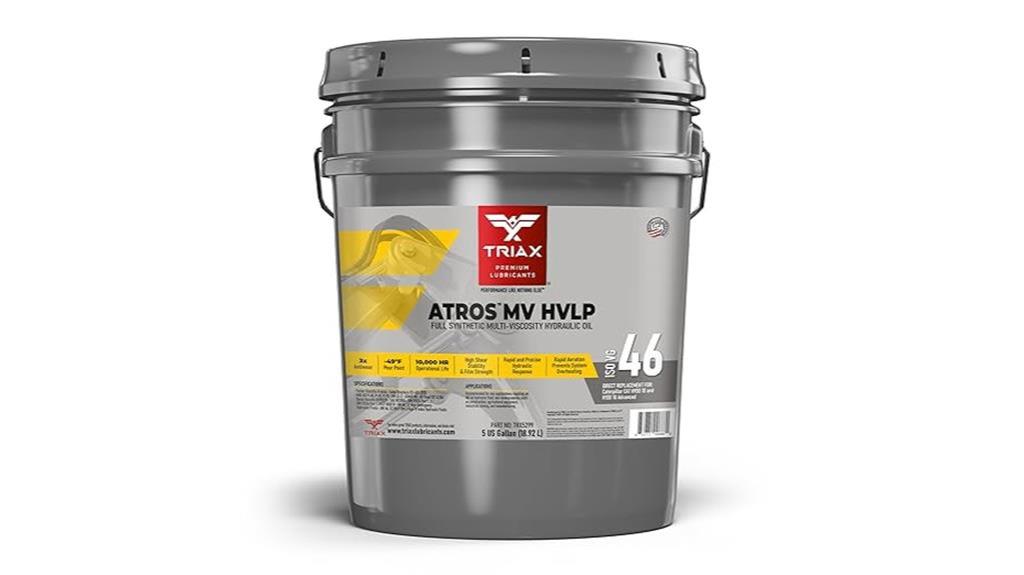

TRIAX Atros MV HVLP Full Synthetic Hydraulic Oil (5 Gallon Pail)

When it comes to maintaining the hydraulic systems of the John Deere 333G, TRIAX Atros MV HVLP Full Synthetic Hydraulic Oil stands out as the ideal choice for operators seeking reliability and performance.

This full synthetic oil boasts a remarkable 300% additive anti-wear boost, providing superior protection for hydraulic components. Its versatility shines through with a multi-vis formulation, replacing various viscosity grades, while delivering true all-season performance.

Operating effectively between -54°F and 150°F, it prevents overheating and guarantees peak hydraulic response. Users appreciate its low foaming characteristics, which guard against cavitation, and report improved performance across diverse equipment.

With a lifespan of 7,000 to 10,000 operational hours, TRIAX Atros MV HVLP truly excels in demanding environments.

Best For: Operators of hydraulic systems seeking reliable, high-performance synthetic oil for demanding applications.

Pros:

- 300% additive anti-wear boost provides superior protection for hydraulic components.

- Multi-vis formulation eliminates the need for multiple viscosity grades, simplifying oil selection.

- Exceptional temperature range from -54°F to 150°F ensures reliable performance in various conditions.

Cons:

- Some users report a faint oily smell in high-pressure applications, which may require additional filtration.

- Initial cost may be higher than conventional hydraulic oils, although it offers long-term savings.

- Limited availability in some regions may make sourcing the product challenging.

Star Fire Premium Lubricants AW 46 Hydraulic Oil, 5 Gallon, Pail

Star Fire Premium Lubricants AW 46 Hydraulic Oil is an excellent choice for operators of the John Deere 333G, thanks to its outstanding wear protection and thermal breakdown resistance.

Formulated with premium base stocks, this 5-gallon pail of hydraulic oil weighs 38 pounds and measures 15.2 x 10.6 x 9.5 inches. It excels in rust prevention, oil oxidation resistance, and maintains excellent water separation properties, ensuring peak performance in hydraulic systems.

Additionally, it features effective foam control and air release, promoting consistent operation. With a customer rating of 4.6 out of 5 stars, users appreciate its performance comparable to pricier options.

Star Fire's AW 46 is a reliable choice for hydraulic-driven pumps, lines, and controls.

Best For: Operators of hydraulic systems, particularly those using John Deere 333G equipment, seeking high-performance and reliable lubrication solutions.

Pros:

- Outstanding wear protection helps extend the life of hydraulic components.

- Excellent thermal breakdown resistance ensures consistent performance in high-temperature conditions.

- High customer satisfaction with a rating of 4.6 out of 5 stars, indicating strong user approval.

Cons:

- Limited availability may require purchasing online rather than in local stores.

- Weight of 38 pounds could be cumbersome for some users when handling or transporting.

- Potentially higher cost compared to some lower-rated hydraulic oils on the market.

TRIAX Agra UTTO XL Tractor Fluid (5 Gallon Pail)

TRIAX Agra UTTO XL Tractor Fluid (5 Gallon Pail) stands out as an exceptional choice for operators of John Deere 333G equipment, thanks to its impressive 6,000-hour oil life in hydraulic systems.

This synthetic blend offers superior performance compared to OEM fluids, with 50% less wear and enhanced friction retention for improved transmission grip. It operates smoothly in extreme temperatures down to -35°F and features virtually zero foaming, ensuring stable hydraulic performance.

Users appreciate its compatibility with various farming equipment and have reported a quieter, smoother operation.

However, shipping issues have been noted, including improper handling of the heavy pails.

Overall, TRIAX Agra UTTO XL provides an excellent balance of quality and value for hydraulic fluid needs.

Best For: Operators of John Deere 333G equipment and other farming machinery seeking high-performance hydraulic fluid.

Pros:

- Outstanding performance with 50% less wear compared to traditional fluids.

- Excellent compatibility with a wide range of farming equipment, ensuring smooth operation.

- Long-lasting oil life of 6,000 hours, reducing the frequency of fluid changes.

Cons:

- Shipping issues reported, including buckets being handled improperly during transit.

- Some customers experienced slight leakage due to poor shipping practices.

- Heavy 5-gallon pails can complicate handling and delivery.

Factors to Consider When Choosing Hydraulic Fluids for John Deere 333G

When choosing hydraulic fluids for your John Deere 333G, you'll want to take into account several key factors.

The viscosity grade, temperature resistance, and additive package all play vital roles in performance and compatibility with your equipment.

Additionally, keep environmental considerations in mind to guarantee you're making a responsible choice.

Viscosity Grade Importance

Choosing the right hydraulic fluid for your John Deere 333G hinges greatly on understanding viscosity grade. This grade is important as it determines how well the fluid flows and lubricates at different temperatures, which is necessary for peak machinery performance.

When you select a hydraulic fluid, a higher viscosity index means the fluid will experience less change in viscosity with temperature fluctuations. This stability is critical for maintaining consistent hydraulic response and effective power transfer.

If you choose a fluid with the wrong viscosity, you risk issues like cavitation, overheating, and accelerated equipment wear. Hydraulic fluids typically come with designated viscosity grades, such as ISO 32, 46, or 68, each suited to specific temperature ranges and operational conditions.

Matching these grades to your equipment specifications is necessary to guarantee reliable performance. In extreme operating environments, whether hot or cold, using fluids with suitable viscosity grades assures that your hydraulic system functions smoothly and that your components last longer.

Temperature Resistance Capability

Understanding viscosity grade is important, but temperature resistance capability plays a significant role in selecting the right hydraulic fluid for your John Deere 333G. You need a hydraulic fluid that performs well in extreme conditions, ideally with a temperature range from -54°F to 150°F. This wide range guarantees that your equipment operates efficiently, no matter the weather.

Look for fluids that maintain viscosity and thermal stability across varying temperatures. This prevents breakdown and guarantees effective power transfer in your hydraulic systems. Pay close attention to the pour point; fluids with lower pour points, around -36°F, guarantee that your hydraulic fluid remains fluid and operational in cold environments, avoiding the risk of thickening.

High viscosity index (VI) values are also significant, as they indicate that the hydraulic fluid can maintain its viscosity through temperature fluctuations. This stability is essential for consistent hydraulic response.

Additionally, effective heat transfer properties in the hydraulic fluid help prevent overheating, guaranteeing your John Deere 333G operates efficiently, even under high-load conditions. Choosing the right hydraulic fluid with excellent temperature resistance will enhance your equipment's performance and longevity.

Additive Package Performance

Selecting the right hydraulic fluid for your John Deere 333G hinges on the performance of its additive package. You'll want to prioritize fluids with excellent anti-wear properties, as some can provide a staggering 300% improvement compared to standard oils. This enhancement is essential for protecting your hydraulic components from wear and tear.

Additionally, focus on additives that offer anti-oxidation and anti-corrosion benefits. These features are significant for maintaining the integrity of your hydraulic system and extending the lifespan of its components.

You should also look for effective foam control and air release capabilities within the additive package. These qualities guarantee consistent operation and help prevent cavitation during high-stress situations.

A high viscosity index is another important factor. It indicates superior thermal stability, which allows your hydraulic fluid to perform reliably across a range of operating temperatures.

Finally, consider the presence of demulsification additives. They play a critical role in managing water separation, preventing emulsions that can lead to corrosion and further wear in your hydraulic system.

Compatibility With Equipment

When evaluating hydraulic fluids for your John Deere 333G, compatibility with the equipment is a top priority. You need to guarantee that the hydraulic fluid you choose meets the specific viscosity requirements outlined by John Deere. This is essential for ideal performance and to prevent any potential equipment damage.

It's also important to select fluids that comply with John Deere's specifications to maintain your warranty coverage. Using non-compliant fluids could jeopardize your warranty and impact the performance of your hydraulic components.

Additionally, look for fluids that exhibit high thermal stability. This will help maintain consistent performance across the varying operating temperatures your machine may encounter.

Another significant factor is the presence of anti-wear additives in the fluid. These additives protect critical components like pumps and cylinders from premature wear, especially during high-pressure applications.

Environmental Considerations

Often overlooked, environmental considerations play an essential role in choosing hydraulic fluids for your John Deere 333G. You need to think about the fluid's biodegradability and its potential toxicity to aquatic life.

Selecting high-performance hydraulic fluids is a smart move, as they often include additives like anti-wear agents and oxidation inhibitors. These not only extend the life of the fluid but also minimize leaks, reducing environmental risks.

Another important factor is the pour point. Fluids with lower pour points guarantee reliable operation in cold conditions, which helps prevent fluid failure and potential spills.

It's also vital to choose fluids with excellent water separation properties. This can help mitigate contamination and corrosion risks, protecting both your equipment and the environment.

Oil Life Expectancy

Understanding oil life expectancy is crucial for maintaining your John Deere 333G's hydraulic system. Hydraulic oils can vary greatly in their oil life, typically ranging from 6,000 to 10,000 operational hours. This variance largely depends on the formulation and additives used in the oil.

When choosing hydraulic fluids, consider full synthetic options, as they generally offer longer oil life due to superior thermal stability and resistance to breakdown under extreme conditions. Additionally, look for oils with enhanced anti-wear additives; these can extend the oil's lifespan by up to 300% more protection compared to conventional oils.

The performance characteristics of hydraulic fluids—such as their ability to maintain viscosity and resist oxidation—also play an important role in oil life expectancy. By selecting the right fluid, you can greatly impact the longevity and efficiency of your hydraulic system.

Regular monitoring and timely changing of hydraulic fluids are crucial, as they help prevent degradation and promote maximum performance. This proactive approach not only prolongs the life of the fluid but also enhances the overall lifespan of your equipment.

Foaming and Cavitation Control

Maintaining the right hydraulic fluid not only influences oil life expectancy but also plays a significant role in controlling foaming and cavitation in your John Deere 333G's hydraulic system. Effective hydraulic fluids should exhibit virtually zero foaming, as this helps prevent hydraulic cavitation, which can cause serious damage to pumps and other components.

When selecting your hydraulic fluid, look for high-quality oils formulated with additives that control foam and enhance air release properties. These additives guarantee stable operation under high-stress conditions, allowing your equipment to perform consistently. The presence of foam can lead to cavitation, resulting in increased maintenance costs and unwanted downtime.

Additionally, consider hydraulic fluids with good demulsification properties, as they enable effective separation of water and contaminants. This further reduces the risk of foaming while improving overall system efficiency.

Opting for a hydraulic fluid with a high viscosity index is also essential; it guarantees thermal stability and shear stability, minimizing foaming and cavitation under varying temperature conditions. By focusing on these factors, you can enhance your John Deere 333G's hydraulic performance and longevity.

Cost-Effectiveness Analysis

Choosing the right hydraulic fluid for your John Deere 333G can greatly impact long-term costs and equipment reliability. When evaluating cost-effectiveness, consider the operational lifespan of the oil. Synthetic fluids often provide 7,000 to 10,000 hours of use, while traditional oils may require more frequent changes, leading to higher operational costs.

Evaluate the additive technology as well; fluids with superior anti-wear properties can notably reduce maintenance expenses and prolong equipment life.

Don't overlook the viscosity index—opt for fluids with a higher index, like 194, which maintain performance across a broader temperature range. This versatility could minimize the need for multiple products.

Improved fuel efficiency and reduced downtime also play an essential role. Enhanced hydraulic response and power transfer capabilities can save you both time and money.

Finally, consider overall compatibility and performance in various applications. A versatile fluid can simplify your inventory needs, cutting down on costs associated with stocking multiple products.

Common Questions

Can I Mix Different Hydraulic Fluids in My John Deere 333g?

Mixing different hydraulic fluids in your John Deere 333G isn't recommended.

Each fluid has unique additives and properties that can interact negatively, potentially harming your machine's performance.

It's best to stick with one type to guarantee peak functionality and avoid any compatibility issues.

If you need to top off the fluid, use the same brand and type.

Always check your owner's manual for specific recommendations regarding hydraulic fluids for your equipment.

How Often Should I Change Hydraulic Fluid in My Equipment?

You should change the hydraulic fluid in your equipment every 1,000 hours of operation or at least once a year, whichever comes first.

Regularly checking the fluid level and condition can help you determine if it needs changing sooner. If you notice discoloration or contamination, it's best to replace it right away.

Keeping up with this maintenance will guarantee your equipment runs smoothly and extends its lifespan.

What Is the Temperature Range for Optimal Hydraulic Fluid Performance?

Did you know that hydraulic fluids typically perform best between 100°F and 175°F?

For ideal hydraulic fluid performance, you should keep the temperature within this range. If it gets too hot, the fluid can break down, leading to reduced efficiency and potential damage.

Conversely, if it's too cold, the fluid may thicken, impairing its ability to lubricate and transmit power.

Regularly monitor your equipment's temperature to guarantee it operates smoothly and efficiently.

Are There Any Environmental Concerns With Hydraulic Fluids?

Yes, there are environmental concerns with hydraulic fluids. Many conventional fluids can be harmful if spilled, contaminating soil and water sources.

You should consider using biodegradable options to minimize impact. In addition, the disposal of used hydraulic fluid poses risks, so proper recycling or disposal methods are essential.

You'll want to stay informed about regulations and choose fluids that align with environmentally friendly practices to protect both your equipment and the planet.

How Do I Properly Dispose of Used Hydraulic Fluid?

To properly dispose of used hydraulic fluid, start by collecting it in a sealed, leak-proof container.

Don't mix it with other fluids, as this can complicate disposal.

Check local regulations for disposal options, as many areas have recycling programs or designated drop-off sites.

Some auto shops or waste facilities may accept it too.

Always handle hydraulic fluid carefully, as it can be harmful to the environment if not disposed of correctly.

Wrapping Up

In the world of heavy-duty machinery, choosing the right hydraulic fluid is like finding the perfect fuel for a race car. With TRIAX Atros MV HVLP, Star Fire AW 46, and TRIAX Agra UTTO XL, you're not just pouring in oil; you're releasing peak performance and longevity in your John Deere 333G. Picture your machine gliding effortlessly through tough tasks, powered by fluids that promise protection and reliability, ensuring you conquer every challenge with ease.